Image

S. Martin

By combining complementary methods comprehensive knowledge about varying materials states is obtained. The analysis and interpretation of the samples requires the use of simulations/modelling to evaluate the experimental data thoroughly. A wide experience in the following methods and their development is available in the group:

- Generation of defined sample states in multi-component systems on a laboratory scale. Particularly in the case of alloys, it is useful to mimic the effects of alloying elements in complex technical alloys using model alloys based on pure substances,

- Alloys with desired, precise compositions in the electric arc furnace or as thin layers,

- Production of oxides through co-precipitation, calcination, and subsequent heat treatment

- Thermodynamic variables can be measured using calorimetric methods and thermodynamic modelling, specifically the CalPhaD method,

- Application of X-ray diffraction for phase identification, crystal structure determination but also for microstructure analysis; use of Rietveld refinement for modelling experimental diffractograms to determine quantitative structural parameters,

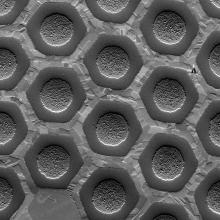

- Scanning electron microscopy analysis including energy-dispersive X-ray spectroscopy (EDS) and electron backscatter diffraction (EBSD), but also special imaging modes (ECCI).