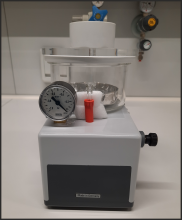

The VACUUM-SET 9117 from KULZER is a compact device that has been developed for embedding and surface impregnation of (porous) metallic, ceramic and mineralogical samples in a vacuum. It consists of a plastic housing with a built-in vacuum pump, a vacuum pot made of glass with a diameter of 100 mm and an acrylic glass lid with a rubber seal to which a silicone rubber funnel can be attached. The device is designed for processing up to 50 samples per day and offers simple and safe handling.

To use the device, the embedding mould together with the sample is placed in the vacuum pot, which is then covered with the acrylic glass lid and sealed airtight with the filling funnel and the matching glass plug. After switching on the device using the cord switch, the vacuum pump starts to build up a vacuum <= 0.6 bar. The vacuum level can be read off using the pressure gauge and adjusted using the adjusting screw on the vent valve. The filling funnel enables the embedding material to be introduced, which flows into the embedding mould by slowly turning the plug. The embedding mould can be removed for hardening of the sample as soon as the air bubbles have been removed from the embedding compound by repeatedly creating a new vacuum. Once the embedding has hardened, the embedding mould is removed and made available for further processing.

If you need to use the vacuum set, please contact the person responsible for the device.