Hybrid Manufacturing of Metals

The Scheme for Promotion of Academic and Research Collaboration (SPARC) is a flagship international mobility and research funding initiative of the Ministry of Education, Government of India. The program is designed to strengthen global academic and research partnerships by enabling structured collaboration between leading Indian higher-education institutions and top-ranked universities and research organizations worldwide. SPARC supports joint research activities, faculty and researcher mobility, and knowledge exchange with institutions from 28 strategically selected countries, with the objective of addressing research challenges of both national and international significance.

Research Focus:

- Hybrid manufacturing.

- Directed energy deposition with arc, laser and electron beam

- Pre-heating and pneumatic hammering

- Mechanical and metallurgical testing.

- Multi-material additive manufacturing

Duration

01.04.2024 to 31.03.2026

Funding

Scheme for Promotion of Academic and Research Collaboration (SPARC) from the Ministry of Education, Government of India.

Main contact

Dr. Neel Kamal Gupta

0373139/2987

neel [dot] gupta [at] imkf [dot] tu-freiberg [dot] de

Research Team

Prof. Henning Zeidler

Dr. Rezo Aliyev

Dr. Neel Kamal Gupta

Visit of Prof. Henning Zeidler at IIT Bombay in February 2025

Prof. Henning Zeidler, Chair of Additive Manufacturing at the Institute for Machine Elements, Engineering Design and Manufacturing (IMKF) at TU Bergakademie Freiberg, Germany, has been leading significant research advancements in the field of additive manufacturing. His research primarily focuses on metal and non-metal additive manufacturing technologies, with different materials and plasma electrolytic polishing as post-processing of metal components. Prof. Zeidler and his metal research group are actively working on arc and laser-based AM, encompassing a wide range of materials, including various grades of steel, copper, and other metallic alloys, as well as bi-metal and multi-material combinations. In addition, his research addresses process development, material behaviour, and application-oriented solutions aimed at enhancing the performance, reliability, and industrial applicability of additive manufacturing systems.

During his visit to IIT Bombay, he delivered a lecture on “Additive Manufacturing – current research approaches at TU Bergakademie Freiberg”, and he talked about the additive manufacturing and comparison with other techniques and the research interest at his chair of Additive Manufacturing.

Visit of Prof. K. P. Karunakaran at TUBAF in December 2025

Prof. K. P. Karunakaran, Coordinator of the Rapid Manufacturing Laboratory and Professor in the Department of Mechanical Engineering at the Indian Institute of Technology Bombay, has over 25 years of experience in the field of additive manufacturing. His long-standing research contributions span the field of machine building, process development, system integration, and industrial deployment of additive manufacturing technologies. In recent years, his primary research focus has been on metal hybrid manufacturing, particularly the integration of additive and subtractive processes for high-performance engineering applications.

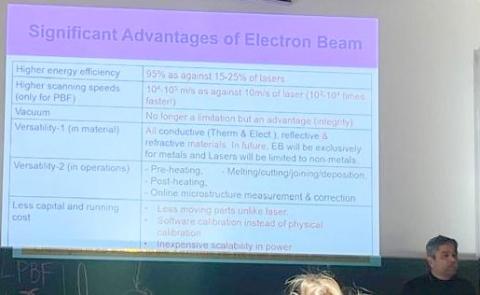

During his visit to TU Bergakademie Freiberg (TUBAF) under the joint mobility program of the SPARC project, Prof. Karunakaran delivered a lecture entitled “Electron Beam Hybrid Manufacturing”. In this talk, he presented his ongoing research on electron-beam-based hybrid manufacturing systems utilizing both powder- and wire-feedstock approaches. His talk highlights the advantages of electron beam over laser and arc-based manufacturing systems. These research projects are funded by the Government of India and involve active collaboration with industry partners, with a strong emphasis on enhancing process reliability, scalability, and suitability for industrial applications.