Flexibly combinable cross-reality labs in university teaching: sustainable skills development for learning and working 4.0

The internships that support teaching, some of which are already known from school days in the subjects of physics and chemistry, not only help to consolidate the understanding of a subject area, but above all stimulate interest and curiosity. This is precisely the aim of the internships offered at universities. Particularly in practice-orientated subjects such as chemistry, process engineering and mechanical engineering, independent work on test stands enables students to apply and test their own knowledge. Mistakes made in the course of setting up experiments also contribute to the students' expertise. The last two years have shown how quickly such practical teaching units can be dropped from university programmes due to various circumstances.

The CrossLab project aims to counteract this. It is tackling this in various areas. In addition to the development of new virtual labs that can be operated remotely, the possibilities of existing digital labs are also to be expanded. At present, only a small number of lecturers from their own courses can use and operate them. Due to the static configuration with a clearly defined learning objective and fixed parameter input and output or parameter selection, it is difficult to transfer and use the lab in other courses. The CrossLab project aims to close this gap. The aim is to develop concepts for the modularisation of digital laboratories.

According to project manager Sebastian Zug, "the variability to adapt the laboratory configuration to teaching or to combine it variably in the sense of Industry 4.0 is [currently] lacking". The joint project, funded with 4.8 million euros by the Innovation in Higher Education Foundation, is based on an interdisciplinary exchange of expertise between Dortmund University of Technology, Ilmenau University of Technology, Nordakademie - Hochschule der Wirtschaft and TU Bergakademie Freiberg.

Methods for designing remote teaching content on existing machines have already been developed at the Chair of Additive Manufacturing. The 3D laboratory offers students the opportunity to produce components using Octoprint on the already installed FFF (Fused Filament Fabrication) machines.

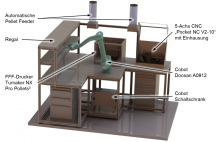

A complete, remotely operated desktop production line is also being installed as part of the CrossLab project. This will make various basic manufacturing processes accessible to students, such as primary moulding (additive manufacturing using FFF) and cutting (machining with a specific cutting edge using 5-axis CNC). Quality control will be made possible using a camera. Finally, the printed components are placed on a shelf for collection. The interface transfer and storage is realised by a controllable cobot.

Project partners

Technische Universität Dortmund, Germany

Technische Universität Ilmenau, Germany

Nordakademie - Hochschule der Wirtschaft, Germany

Project duration

08/2021 - 12/2025

Funding

The project is funded by the Stiftung Innovation in der Hochschullehre (StIHL).

Dr.-Ing. Stefan Krinke

stefan [dot] krinke [at] imkf [dot] tu-freiberg [dot] de (stefan[dot]krinke[at]imkf[dot]tu-freiberg[dot]de)

03731/39 3231

Agricolastraße 1

Karl-Kegel-Bau

09599 Freiberg