FUL-MUS - Functional integration and lightweight construction with additive manufacturing in musical instrument making

The overarching aim of the sub-project is to investigate the potential of functional integration and lightweight construction through additive manufacturing in musical instrument making. Theoretical and experimental analyses along the entire process chain on representative components will be used to investigate the technical and technological possibilities for integrating musical instrument parts from both a design and manufacturing perspective. Based on this, a design guideline for the industrial implementation of the concept is to be developed in order to provide targeted support to companies in the industry.

Project partners

Additive Drives GmbH

Instrumentenbau Jürgen Voigt GmbH & Co. KG

Technical University Bergakademie Freiberg (TUBAF)

Westsächsische Hochschule Zwickau

Project duration

01.05.2023 - 30.04.2025 (extension sought until 31.12.2025)

Main contact

Prof. Dr.-Ing. Henning Zeidler

+49 3731 39 3066

additive_fertigung [at] imkf [dot] tu-freiberg [dot] de

Research team

Prof. Dr.-Ing. Henning Zeidler

Dipl.-Ing. Toni Böttger

Dr.-Ing. Stefan Krinke

Dipl.-Ing. Martin Krinke

Work package 1 - Discussion of the potential for functional integration of parts

Work package 1 (WP 1) comprises the analysis of the variety of geometries, which TUBAF carries out in collaboration with the user in order to identify and catalogue components that can be integrated. The central criteria here are the combination of components that enable a reduction in the weight of the instrument and the number of parts to be manufactured, thus reducing the manufacturing effort. When selecting the individual components, their effects on the sound characteristics of the instrument are also evaluated and taken into account during subsequent integration.

Once the relevant components have been determined, their geometry and surfaces are analysed to create a list of requirements. This list contains all the essential test criteria from the perspective of instrument construction. In addition to shape, surface finish and material, other relevant aspects such as tolerances and complexity parameters are also systematically recorded.

Work package 2 - Development of a customised process chain for the additive manufacturing of function-integrated parts

In work package 2 (WP 2), TUBAF takes the lead in preparing and conducting experimental investigations into the achievable geometries and surface qualities. These investigations are based on the musical instrument parts identified in WP 1 and the corresponding additive manufacturing processes. As integral components have different design characteristics, existing process chains must be adapted, taking into account the design freedom of additive manufacturing.

In this work step, the technology used to ensure specific surface properties with regard to sound characteristics is identified and systematised. ADDITIVE DRIVES then supports the teams in the adaptation and production of the integral components, with a particular focus on the use of additive manufacturing.

The achievable geometry and surface properties are characterised using tactile and/or optical measurement methods. The results obtained enable a detailed description of the cause

Work package 3 - Post-processing of integral components (including functional surfaces) for better sound properties

Work package 3 deals with the optimal post-processing of additively manufactured integral components. All project partners are working closely together in this context to develop a multi-stage post-processing strategy, as a rough surface cannot be brought to the target contour and the required quality ensured in a single process step. The aim is to produce visually appealing components by combining established processes as flexibly and economically as possible.

A particular focus is on optimising the varying surface conditions caused by the geometry, which deliver different results depending on the post-processing method. A promising approach to reducing the influence of surface preference directions is the expansion of the finishing processes through the use of locally coupled ultrasound.

In addition to the qualitative analysis of the surfaces, subjective criteria such as haptics and the tonal evaluation of sound-producing components are also included in the final analysis. The results of the post-processing investigations are systematically analysed and summarised in a database for specific materials.

Work package 4 - Development of special design guidelines for the functional integration of the parts

In work package 4, TUBAF is developing a design guideline for functional consolidation by merging components in musical instruments. This reduces the number of interfaces, which requires targeted design customisation. In addition, a methodical procedure for selecting suitable materials from a prepared matrix is intended to facilitate the work of designers. It is assumed that similar integral components can be used for some musical instruments. These special shapes and structures are systematised and provided as partial solutions.

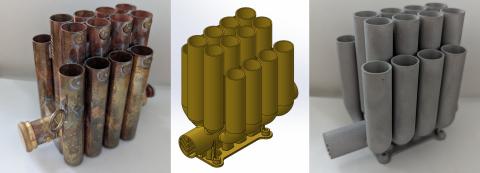

Work package 5 - Implementation of the developed design guideline and technology on a demonstrator

In the final work package 5, the results from work package 4 are implemented in a demonstrator. Together with VOIGT, BERDANI and ADDITIVE DRIVES, TUBAF manufactures the integral components, which are designed in accordance with the new design guidelines. The demonstrators are then integrated into a musical instrument and tested by the project partners. During the test phase, WHZ will use its acoustic expertise to support the users in evaluating the sound properties of the new components.

In the final step of work package 5, the results will be evaluated together with the project partners and further measures for the utilisation of the work results will be coordinated. In addition, the project results and knowledge gained will be documented in order to make them usable for possible future development steps.