Project description

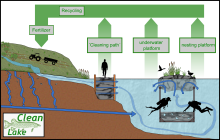

The CleanLake project started on 01.06.2024. A new type of water treatment system is to be developed over a three-year project period. The basis of the resulting products will be sorption materials obtained from industrial by-products such as fly ash and coal stockpile. These materials should help to significantly reduce the input of fertilizers into fresh water and thus sustainably improve water quality. In order to counteract eutrophication most effectively, both the tributaries and the lake itself are to be cleaned. This results in several end products.

Design elements such as paths, nesting platforms for water birds and underwater habitats are to be provided for seasonal use. As soon as the sorptive materials have exhausted their capacity to absorb nitrogen and phosphorus compounds, they will be recycled and converted into fertilizers with controlled nutrient release. The project consortium is thus developing innovative materials that can be directly integrated into new products. Because of this, the technology promotes a modern circular economy.

Installation of the first prototype of a floating filter platform

First, a prototype of a floating filter platform was built: a filter basket was attached to a ring made of PVC pipe as a float via an aluminium profile frame. This was initially filled with natural zeolite as a sorption material for fertiliser residues (phosphates, nitrates). A small pump in the central collection pipe pumps water upwards, similar to a well. Water then flows in from the outside through the outer surface of the filter basket. This ensures a continuous and even flow through the zeolite bed and maximum filter performance. The pumped and filtered water is returned to the water body a few metres away. A former quarry, now the ‘Riesenstein’ diving centre in Meissen, was selected as the test site.

In the future – following a successful initial test run – the filter basket will be filled with optimised artificial zeolite in order to increase the separation performance and thus the filtering effect on the water. In addition, in a later, larger-scale application, the platform can be greened to better meet ecological and aesthetic requirements. The filter basket can also be lowered to different water depths to better accommodate seasonal water stratification.

Work Packages

The research for the CleanLake project is divided into individual work packages (WP). The different technical expertise of the project partners results in different responsibilities, whereby the project is also characterized by intensive cooperation between the work packages.

Cracow University of Technology (CUT, coordinator, Poland)

- Overall coordination of the project (scientific, administrative, IPR management)

- Development and characterisation of materials (zeolites, geopolymers)

- Prototype design (‘cleaning path’, platforms) and laboratory tests

- Recycling and fertiliser development (granules with controlled nutrient release)

- Leadership in patent applications and publication strategy

Vilnius Gediminas Technical University (VGTU, Lithuania)

- Leadership in the synthesis of zeolites from waste materials (WP1)

- Development of geopolymers and composites with zeolites

- Characterisation of raw materials (e.g. fly ash, biomass ash)

- Participation in prototype design and recycling strategies

Contributions to publications and international collaborations

Technical University Bergakademie Freiberg (TUBAF, Germany)

- Leadership in the development of composites for lake infrastructure (WP2)

- Planning, construction and installation of prototypes in Germany (Riesenstein diving site and another lake)

- Underwater research and scientific diving (placement, sampling, monitoring)

- Laboratory tests on mechanical and fluid dynamic properties

- Contribution to publications and patent applications

Adam Mickiewicz University Poznań (AMUP, Poland)

- Selection of suitable lakes in Poland for prototype testing

- Environmental monitoring: water quality, flora and fauna, bioindicators

- Evaluation of the effectiveness of prototypes against eutrophication

- Participation in the development and testing of recycled fertilisers

- Contributions to environmental analyses and publications

PROTE Technologie dla Środowiska (PROTE, Poland)

- Industrial partner with a practical focus

- Construction, installation and testing of prototypes (in particular ‘cleaning path’)

- Conducting field work and monitoring

- Development of strategies for commercialisation and market launch

- Contact for certification and scaling of technologies