Project description

M-ERA.NET Call 2021

Projectnumber: 100639965

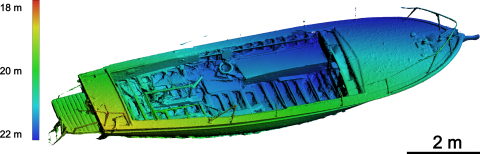

The aim of the project is to develop a cost-effective material for 3D printing underwater based on geopolymers to safely contain hazardous substances and eliminate the risk associated with dangerous shipwrecks. The main objective of the project is to develop high-performance composites with functional properties for technical applications such as the construction and marine industries. The planned result is an environmentally friendly, high-performance composite material for underwater applications. It is the answer to the need for more durable materials to protect hazardous wrecks and critical underwater infrastructure from corrosion and also for construction purposes in harsh environments, including highly polluted environments, including protection from hazardous cargo in wrecks. The result will be potentially interesting for government institutions planning to increase activities related to environmental protection (protection of hazardous wrecks), as well as for private companies, including underwater works in polluted environments.

Tasks Scientific Diving Centre

The main tasks in the project are

- coordination of the entire project

- monitoring of underwater activities

- thermodynamic simulations

- support in the investigation of prototypes in comparable environments

Project partner:

| Coordinator (P1): Technische Universität Bergakademie Freiberg | Partner 2: Technische Universität Krakau | Partner 3: HYBRID Sp. z o.o. | Partner 4: Technische Universität Liberec |

Short Report

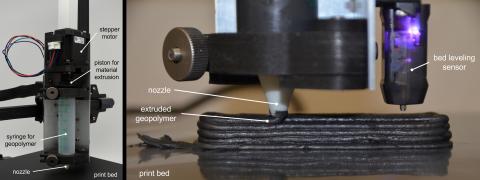

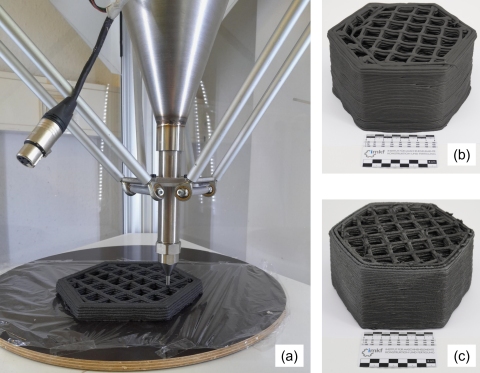

The main goal of the project was to develop high-performance composite materials with functional properties suitable for technical applications in the construction and marine sectors. The material developed as part of the project consisted of the following components: a geopolymer matrix (GP) reinforced with fibres and/or particles. This composition was designed to meet performance requirements that could not be achieved with a single component alone. The matrix, fibres, particles and fillers were sourced from both mineral and synthetic sources.

The project led to the development of environmentally friendly, high-performance composites for underwater applications. These materials met the need for more durable solutions to protect hazardous wrecks and critical underwater infrastructure from corrosion, as well as to support construction activities in harsh or heavily polluted environments. The developed elements were manufactured as prefabricated or 3D-printed components that can be installed underwater. Their geometries were specifically tailored to specific wrecks or underwater locations. Compared to conventional construction and repair materials, the materials demonstrated improved corrosion resistance, increased durability, better workability, cost efficiency and architectural adaptability.

MAR-WRECK had a strong scientific character and focused on developing innovative products and advanced technologies demanded by the market. The project responded to societal and industrial needs. The materials developed offered environmental benefits due to their low carbon footprint and the use of raw materials from waste. The final composite products could be used for environmental protection, including protecting hazardous wrecks and other critical underwater structures from corrosive environments.

Publications

- B. Gharehpapagh, M. Denker, S. Gadek, R. Gruhn, T. Grab, K. Korniejenko, H. Zeidler (2025)

Geopolymer Materials for Additive Manufacturing: Chemical Stability, Leaching Behaviour, and Radiological Safety

MDPI - Materials, DOI: 10.3390/ma18214886 - M. Denker, B. Gharehpapagh, R. Gruhn, S. Pose, K. Korniejenko, T. Grab, H. Zeidler (2025)

Compressive strength of geopolymer with recycled carbon fibres manufactured in air and in water by casting and additive manufacturing

Frontiers in Built Environment - Construction Materials, DOI: 10.3389/fbuil.2025.1620385 - K. Oliwa, B. Kozub, K. Los, P. Los, K. Korniejenko (2025)

Assessment of Durability and Degradation Resistance of Geopolymer Composites in Water Environments

MDPI - Materials, DOI: 10.3390/ma18163892 - A. Becher, H. Zeidler, S. Gądek, K. Korniejenko. (2025)

Shaping and Characterization of Additively Manufactured Geopolymer Materials for Underwater Applications

MDPI applied sciences, DOI: 10.3390/app15073449 - K. Korniejenko, S. Gądek, P. Dynowski, D.H. Tran, M. Rudziewicz, S. Pose, T. Grab. (2024)

Additive Manufacturing in Underwater Applications

Appl. Sci. 2024, 14, 1346. DOI: 10.3390/app14041346 - V. Růžek, A. M. Dostayeva, J. Walter, T. Grab, K. Korniejenko. (2023)

Carbon Fiber-Reinforced Geopolymer Composites: A Review

MDPI Journal fibers, DOI: 10.3390/fib11020017

This measure is co-financed with tax revenue based on the budget approved by the Saxon State Parliament.