Project manager:

- martin [dot] abendroth [at] imfd [dot] tu-freiberg [dot] de (Dr.-Ing. Martin Abendroth)

- bjoern [dot] kiefer [at] imfd [dot] tu-freiberg [dot] de (Prof. Dipl.- Ing.Ing. Björn Kiefer, Ph.D.)

Project staff:

- Dr.-Ing. Johannes Storm (2011-2015)

- Dr.-Ing. Christoph Settgast (2015-2019)

- Dr.-Ing. Alexander Malik (2019-2023)

Motivation and objectives

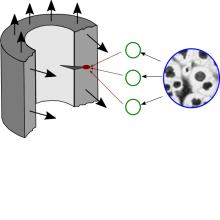

Porous ceramic structures, which are characterised by high thermal resistance and good design options for filter structures, are predominantly used to filter liquid metals. In addition to functional properties such as porosity, filtration efficiency, flow behaviour and chemical reactivity, which are key to filter quality in molten metal treatment, the mechanical properties of the filter also play an important role. The partial or total breakage of a filter system causes considerable technological damage and contamination of the melt. If the filter material deforms too much as a result of pressure softening, the filter function is severely impaired or even completely prevented by clogging. It is therefore essential to ensure the strength of the filter material and the filter structure as a component against thermal and mechanical stresses during the filtration process. This applies to resistance to single or repeated thermal shock and viscoplastic deformation during the stresses caused by the molten metal. In order to technologically increase the melt throughput, filters with diameters > 200 mm will be required in future, which will lead to disproportionate bending stresses, pressure softening and larger temperature gradients. Due to the geometrically complex design of highly porous filter structures such as ceramic foams, etc., the evaluation of thermal shock and creep behaviour can only be solved using a multi-scale modelling approach and numerical simulations.

The aim of the project is to develop meso- and macroscopic material models and to provide simulation tools for evaluating the thermal shock resistance and pressure softening of specific filter structures. The project thus serves as an interface to the materials science investigations in project area C of the SFB 920 and also creates a bridge to the research, optimisation and design of new, more complex filter systems in project area A.

When creating the computer-generated model, the SurfaceEvolver software can be used to simulate interfaces with minimal surface energy. For the simulation of foams, this method

can be used to generate the PU backbone, which is ultimately bordered by an interface between computer-generated Kelvin cell bubbles and the fluid of a PU foam. Furthermore, this can be used to approximately describe the impregnation and spray coating process, in which a defined volume of liquid (slurry) is distributed on the base structure in such a way that the surface area of the solid part is minimised. A volume model can be generated from these physically based surface meshes which, in conjunction with the developed material law, can be used in the FEM to calculate the local stress and strain fields under systematically varied external loads. The local stress and strain fields can be used to derive criteria that can be used to make statements about the onset of non-elastic deformations or failure as a result of critically loaded cracks.

Publications

- Abendroth, M., Hütter, G., Settgast, Chr., Malik, A., Kiefer, B., Kuna, M.: A Hybrid Approach to Describe the Elastic-Plastic Deformation Behavior of 2D Cellular Solids Including Damage Effects, Technische Mechanik 40-1 (2020) pp. 5–14 (DOI: 10.24352/UB.OVGU-2020-008)

- Settgast, C., Hütter, G., Kuna, M., Abendroth, M.: A hybrid approach to simulate the homogenized irreversible elastic–plastic deformations and damage of foams by neural networks, International Journal of Plasticity (2020) 102624 (DOI: 10.1016/j.ijplas.2019.11.003)

- Herdering, A., Abendroth, M., Gehre, P., Hubálková, J., Aneziris, C.: Additive manufactured polyamide foams with periodic grid as templates for the production of functional coated carbon-bonded alumina foam filters, Ceramics International 45 (2019) pp. 153-159 (DOI: 10.1016/j.ceramint.2018.09.146)

- Storm, J., Abendroth, M., Kuna, M.: Effect of morphology, topology and anisoptropy of open cell foams on their yield surface, Mechanics of Materials 137 (2019) pp. 103145 (DOI: 10.1016/j.mechmat.2019.103145)

- B. Luchini, E. Storti, T. Wetzig, C. Settgast, M. Abendroth, J. Hubálkova, V.C. Pandolfelli, C.G. Aneziris: Mechanical and physical characterization of Al2O3–C foam filters produced by distinct processing routes: The importance of the ceramic strut morphology, Journal of the European Ceramic Society (DOI: 10.1016/j.jeurceramsoc.2019.02.048)

- C. Settgast, M. Abendroth, M. Kuna: Constitutive modeling of plastic deformation behavior of open-cell foam structures using neural networks, Mechanics of Materials (DOI: 10.1016/j.mechmat.2019.01.015)

- C. Settgast, Y. Ranglack-Klemm, J. Hubalkova, M. Abendroth, M. Kuna, H. Biermann: Validation of an experimental-numerical approach for the high temperature behaviour of open-cell ceramic foams, Journal of the European Ceramic Society (DOI: 10.1016/j.jeurceramsoc.2018.09.022)

- C. Settgast, G. Hütter, M. Abendroth, M. Kuna: A Hybrid Approach for Consideration of the Elastic-Plastic Behaviour of Open-Cell Ceramic Foams, Proceedings of the 6th European Conference on Computational Mechanics (ECCM-ECFD), ISBN: 978-84-947311-6-7 (2019) S. 2314-2325

- C. Settgast, M. Abendroth, M. Kuna: Investigation of creep behavior of open cell ceramic Kelvin foam, Proceedings of the International Conference on Creep and Fracture of Engineering Materials and Structures (Creep2017), ISBN: 978-5-7422-5799-8 (2017) S. 166-167

- E. Werzner, M. Abendroth, C. Demuth, C. Settgast, D. Trimis, H. Krause, S. Ray: Influence of Foam Morphology on Effective Properties Related to Metal Melt Filtration, Advanced Engineering Materials (DOI: 10.1002/adem.201700240)

- M. Abendroth, E. Werzner, C. Settgast, S. Ray: An Approach Toward Numerical Invesigation of the Mechanical Behavior of Ceramic Foams during Metal Melt Filtration Processes, Advanced Engineering Materials (DOI: 10.1002/adem.201700080)

- C. Settgast, J. Solarek, Y. Klemm, M. Abendroth, M. Kuna, H. Biermann: Prediction of High Temperature Behavior of Open-Cell Ceramic Foams Using an Experimental-Numerical Approach, Advanced Engineering Materials (DOI: 10.1002/adem.201700082)

- C. Settgast, M. Abendroth, M. Kuna: Fracture Mechanical Analysis of Open Cell Ceramic Foams Under Thermal Shock Loading, Journal of Multiscale Modelling (DOI: 10.1142/S1756973716400060)

- C. Settgast, M. Abendroth, M. Kuna: Bruchmechanische Analyse von offenzelligen keramischen Schäumen (Fracture mechanical analysis of open cell ceramic foams), DVM-Bericht 248 (2016) S. 51-60

- C. Settgast, M. Abendroth, M. Kuna: Fracture mechanical analysis of open cell ceramic foams under multi-axial mechanical loading, Archive of Applied Mechanics (DOI: 10.1007/s00419-015-1107-3)

- J. Storm, M. Abendroth, M. Kuna: Numerical and analytical solutions for anisotropic yield surfaces of the open-cell Kelvin foam, International Journal of Mechanical Sciences (DOI: 10.1016/j.ijmecsci.2015.10.014 ).

- D. Zhang, M. Abendroth, M. Kuna, J. Storm: Multi-axial brittle failure criterion using Weibull stress for open Kelvin cell foams, International Journal of Solids and Structures (DOI: 10.1016/j.ijsolstr.2015.04.020 ).

- C. Voigt, J. Storm, C.G. Aneziris, M. Abendroth, M. Kuna, J. Hubalkova: The influence of the measurement parameters on the crushing strength of reticulated ceramic foams, Journal of Materials Research. Vol. 28. Iss. 17 (DOI: 10.1557/jmr.2013.96)

- J. Storm, M. Abendroth, M. Kuna: Geometry dependent effective heat conductivity of opencell foams based on Kelvin cell models, Unitecr 2013 Conference Proceedings.

- J. Storm, M. Abendroth, D. Zhang, M. Kuna: Geometry dependent effective elastic properties of open-cell foams based on Kelvin cell models, Advanced Engineering Materials (DOI: 10.1002/adem.201300141).

- J. Storm, M. Abendroth, M. Emmel, Th. Liedke, U. Ballaschk, C. Voigt, T. Sieber, M. Kuna: Geometrical modelling foam structures using implicit functions, International Journal of Solids and Structures (DOI: 10.1016/j.ijsdstr.2012.10.026).

- J. Hein, J. Storm, M. Kuna: Numerical thermal shock analysis of functionally graded and layered materials, International Journal of Thermal Sciences (DOI: 10.1016/j.ijthermalsci.2012.05.005).

- J. Storm, J. Hein, M. Kuna: Numerical Study to Optimize Thermal Shock Resistance of a FGM Nozzle refractories, WOLRDFORUM (2012) 1, 175-180.

Conferences

- CELLMAT 2020: A. Malik, M. Abendroth, B. Kiefer, Applications of a hybrid approach to describe the elastic-plastic deformation behavior of highly porous media by neural networks

- 6th International Conference on Material Modelling (ICMM), 2019, Lund (Sweden): C. Settgast, G. Hütter, M. Abendroth, M. Kuna, A Hybrid Approach to Describe the Elastic-Plastic Deformation Behaviour of Porous Media Including Damage Effects

- CELLMAT 2018: C. Settgast, Y. Ranglack-Klemm, M. Abendroth, M. Kuna, H. Biermann, On the Creep Deformation Behaviour and Elastic Stiffness of Carbon-Bonded Ceramic Foams

- 6th European Conference on Computational Mechanics (ECCM-ECFD), 2018, Glasgow (Scotland): C. Settgast, G. Hütter, M. Abendroth, M. Kuna, A Hybrid Approach for Consideration of the Elastic-Plastic Behaviour of Open-Cell Ceramic Foams

- 14th International Conference on Creep and Fracture of Engineering Materials and Structures, 2017, Saint Peterburg (Russia): C. Settgast, M. Abendroth, M. Kuna, Investigation of creep behavior of open-cell ceramic Kelvin and stochastic foam

- CELLMAT 2016: C. Settgast, J. Solarek, Y. Klemm, M. Abendroth, M. Kuna, H. Biermann, Mechanical properties of artificial and real open cell ceramic foams

- 15th International Conference on Fracture and Damage Mechanics, 2016, Alicante (Spain): C. Settgast, M. Abendroth, M. Kuna, Fracture mechanical analysis of open cell ceramic foams under thermal shock loading

- 48. Tagung DVM Arbeitskreis Bruchvorgänge 2016 (Deutscher Verband für Materialforschung und -prüfung e.V.): C. Settgast, M. Abendroth, M. Kuna, Bruchmechanische Analyse von offenzelligen keramischen Schäumen

- Gamm 2014 (Gesellschaft für angewandte Mathematik und Mechanik): J. Storm, M. Abendroth, M. Kuna, C. G. Aneziris, Elastic-plastic homogenization of open-cell foams based on Kelvin cell models

- CELLMAT 2014: J. Storm, M. Abendroth, M. Kuna, Elastic and Visco-Plastic Homogenization of Open-Cell Foams Based on Kelvin Cell Models

- CELLMAT 2012: J. Storm, M. Abendroth, M. Emmel, Th. Liedke, U. Ballaschk, C. Voigt, T. Sieber, M. Kuna, Modelling foam structures using implicit functions Proceedings of the Cellular Materials

Poster

- CISM-Course 2017 (International Centre for Mechanical Sciences): C. Settgast, M. Abendroth, M. Kuna, Fracture Mechanical Analysis of Open-Cell Ceramic Foams

- Unitecr 2013 (Unified International Technical Conference on Refractories): J. Storm, M. Abendroth, M. Kuna, Geometry dependent effective heat conductivity of open-cell foams based on Kelvin cell models

- MSE 2012 (Materials Science and Engineering): J. Storm, M. Abendroth, M. Emmel, Th. Liedke, U. Ballaschk, C. Voigt, T. Sieber, M. Kuna, Generating Foam Structures Using Implicit Functions