Project manager:

- geralf [dot] huetter [at] imfd [dot] tu-freiberg [dot] de (PD Dr.-Ing. habil. Geralf Hütter)

- bjoern [dot] kiefer [at] imfd [dot] tu-freiberg [dot] de (Prof. Dipl.-Ing. Björn Kiefer, Ph.D.)

Project staff:

- Dr.-Ing. Omar El Khatib

Project partner:

Motivation and objectives

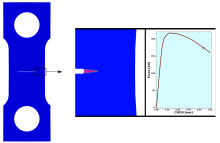

Fault-tolerant component design ensures that any existing crack-like defects do not lead to the failure of a component. In many cases, such faults or material defects cannot be ruled out for manufacturing reasons or arise during operation due to material fatigue, creep or corrosion. For safety-relevant components, a fracture-mechanical strength verification assuming postulated cracks is therefore required for approval or continued operation. In other areas, a fault-tolerant design in combination with appropriately coordinated maintenance intervals allows a much more efficient use of materials and a lighter construction. In such a fracture-mechanical or fault-tolerant design, the stress at the tip of a crack in the component is quantified. Crack initiation or component failure are ruled out if the crack tip stress in the component is below a material-specific crack toughness.

The crack toughness is determined in accordance with applicable regulations using standard specimens, which have a high strain constraint in the area of the crack tip and thus a high local stress multi-axiality. As the crack toughness increases with decreasing constraint, the crack toughness determined on standard specimens with a high constraint forms a lower limit, so that a design based on this may be too conservative. As a result, too small permissible defect sizes are determined in a component, its remaining service life is underestimated, maintenance intervals are set too short or the component is unnecessarily oversized.

By developing a validated calculation method for taking the constraint into account in the fracture mechanics design of components made of ductile materials and implementing it in relevant regulations, the use of materials can be reduced and the service life and maintenance intervals optimised without jeopardising the safety of components and systems.

Funded by the Federal Ministry for Economic Affairs and Energy on the basis of a decision by the German Bundestag as part of IGF project no.: 21703 BG