The rational design of catalysts comprises a stringent concept for the targeted development of new catalyst materials for various chemical processes, particularly in the areas of exhaust gas purification and fuel synthesis. The procedure covers a broad spectrum of scientific and methodological aspects, ranging from the preparation, characterization and testing of materials to mechanistic and kinetic investigations and the implementation of catalysts in suitable chemical reaction apparatus. The main steps involved are outlined below:

- Preparation of solid catalysts using classical and novel methods (e.g. precipitation, flame spray pyrolysis, ultrasound, complexation)

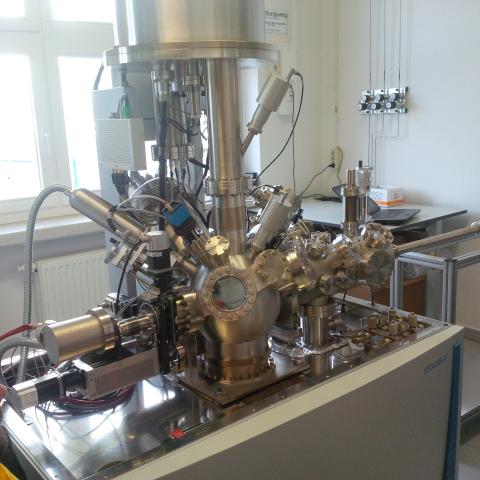

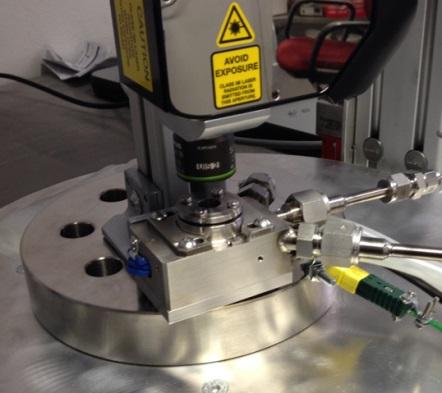

- Physico-chemical characterization of catalysts using surface and solid-state analytical methods

(e.g. XPS, Raman, UV/Vis, DRIFTS, ATR-IR, Mössbauer, XRD, SEM, XRF, BET) - Determination of catalytic activity and selectivity under atmospheric and high-pressure conditions

- Characterization and structure elucidation of gaseous and liquid reaction products using differentiated analytics (e.g. FTIR, GC/WLD/FID, GC/MS)

- Creation of structure-activity correlations to identify catalytically active centers and, based on this, targeted preparation of catalysts

- Elucidation of reaction mechanisms using in situ and operando techniques (DRIFTS, UV/Vis/DRIFTS/MS, Raman, XPS, XRD)

- Evaluation of the kinetics of chemical reactions in integral and gradient-free reactors under steady-state and transient conditions

- Development of global and elementary models for the description of reaction kinetics

- Modeling of chemical reactors to calculate conversion and temperature profiles

- Design of technical reactors and process simulation based on valid reactor models