Vision

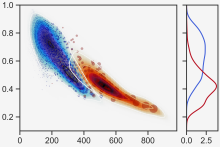

Mechanical process engineering, including particle technology, is one of the key areas in engineering sciences for future technological megatrends. In the future, it will be important to provide a more accurate description of dispersed particle systems in order to derive more detailed structure-property relationships (property functions). In this context, the use of multidimensional particle property distributions is the focus of work at the MVTAT Institute.

The distributed properties of the particle systems make particle processes an ideal case for data-driven research and development, especially as the particle systems become more complex. This will also enable us in the future to elevate the traditional, predominantly empirical approaches of mechanical process engineering (process function) to a new, significantly more precise level.

Teaching Concept

Teaching in the field of Mechanical Process Engineering is conducted in the German-language degree programs of Chemieingenieurwesen / Verfahrenstechnik (Diploma / Master), Engineering (Bachelor), and Mechanical and Process Engineering (Master in English). In addition to the respective fundamental modules, which provide an introduction to the world of particles and particle processes, modules in the area of Mechanical Separation Technology, Recycling, and related equipment technology are offered. Particularly in the English-language lectures, accompanying digital resources are provided, utilizing either specially produced screencasts or lecture recordings.

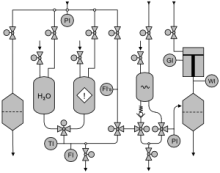

At the MVTAT Institute, practical content is also emphasized in teaching. Mechanical Process Engineering heavily relies on experimentally determined characteristic values. Therefore, the lab content of the modules places importance on the measurement of such values through defined lab experiments (e.g., according to VDI 2762). The experimental training includes planning the lab experiment, conducting it, analyzing the digitally provided data sets, and deriving the corresponding characteristic values. These values are then used for quantitative design calculations.

International Teaching

The English-language master's program in Mechanical and Process Engineering, of which I have been the dean since its introduction in 2016, is also home to two mobility programs. The EMerald program is an Erasmus Mundus program in cooperation with the universities of Liège (Belgium), Nancy (France), and Luleå (Sweden), and trains engineers with an additional background in geosciences and resource technology. The ENTER study program emerged from a project by EIT RawMaterials and has a special mobility scheme for students from various partner universities in Eastern and Southeastern Europe. ENTER is organized in cooperation with the Lappeenranta University of Technology (Finland) and offers a comprehensive engineering education with various opportunities for starting one's own business. Due to the strong integration of both study programs into EIT RawMaterials, aspects of entrepreneurship are specifically taught, among other things, in accompanying summer schools; both programs also carry the EIT RawMaterials label of excellence.

Research Approach

The relevance of particle systems for many forward-looking technical themes of our industrial society is also reflected in our research topics. The issue of sufficient resource provision is a central theme in processing technology. Thus, recycling processes and new separation approaches are being researched, which are adapted to the complex structures and varying material contents of future technologies (batteries, electrolyzers, electronic components, additively manufactured components, composite materials). Likewise, attention must be paid to the availability, i.e., processing, of new primary raw material sources and critical elements.

Conceptually, the two- and multidimensional description of particle systems, combined with their digital capture and processing, offers a broad field to develop new specifications and precise process laws for Mechanical Process Engineering, often driven by data.

Methodologically, we rely on the characterization of particle systems using µ-computer tomography, atomic force microscopy, and imaging approaches that provide us with the necessary information about the particle systems with their multidimensional properties.

The overarching goal is to describe the behavior of these particles in a process engineering process, starting from a detailed (multidimensional) description of the particle system, to come up with new and better particle-based products more effectively and sustainably. The many inter- and intradisciplinary issues require and foster cooperation with many other disciplines, including computer science, mathematics, and the geo- and natural sciences.

Curriculum Vitae

Academic Education

- 1991–1997: Study of Chemical Engineering, University of Karlsruhe

- 1995–1996: Institut National Polytechnique de Lorraine, École Nationale Scientifique des Industries Chimiques, Nancy, France, Prof. P. LeGoff

- 1997: Graduation as Dipl.-Ing.

Scientific Degrees

- 2002: Doctorate: Über die kombinierte Dampfdruck- und Zentrifugalentfeuchtung (On combined steam pressure and centrifugal dewatering), Faculty of Chemical Engineering, University of Karlsruhe (TH), Prof. W. Stahl

- 2005: Mid-term evaluation of the first phase of Junior Professor (Habilitätsäquivalenz), TU Clausthal

Professional Career

- 1997–2002: Research Assistant at the Institute for Mechanical Process Engineering and Mechanics, University of Karlsruhe (TH)

- 2002–2008: Junior Professor for Chemical Apparatus, Institute for Chemical Process Engineering, TU Clausthal

- 2003–2004: Managing Director of the Institute for Chemical Process Engineering, TU Clausthal

- since 2008: Professor (W3) for Mechanical Process Engineering, University Professor, Institute for Mechanical Process Engineering and Processing Technology, TU Bergakademie Freiberg − Managing Director of the Institute

- 2011–2014: Acting Head of the Department of Processing Technology at the Helmholtz Institute Freiberg for Resource Technology (HIF), Helmholtz Center Dresden Rossendorf (HZDR)

- since 2016: Director of the Central Facility of TU Bergakademie Freiberg RCF – Regional Center Freiberg of the EIT RawMaterials

- since 2016: Study Dean of the Master's Program Mechanical and Process Engineering (MPE)

- 2018-2022: Vice Rector for Structural Development at TUBAF

- since 2023: CO TUBAFdigital – Rector's Commissioner

Scientific Affiliations

- Partec: Member of Strategy Committee

- Filtech Europe: Member of Scientific Committee

- WFC: Member of Scientific Committee

- IMPC: Council Member

- Dechema/VDI: Chairman of ProcessNet specialist group "Mechanische Flüssigkeitsabtrennung"

Research Associations

- 2011–2023: DFG SFB 920 – Board Member

- 2016–2024: DFG SPP 2045 – Coordinator

- 2020–2028: DFG SPP 2315 – Koordinator

- 2021–2024: BMBF Cluster GreenBatt Projekt DIGISORT – Project Lead

- 2021–2024: BMBF Cluster GreenBatt Projekt LowVolMon – Project Lead

- 2021–2024: BMBF Verbundprojekt InfraDatRec – Project Lead

- 2021–2025: BMBF H2Giga Verbundprojekt ReNaRe – Project Lead

- 2022–2025: STIHL Verbundprojekt VirtFa – Project Lead

- 2022–2027: Helmholtz Networking Fund Projekt FINEST – Chair Research School

Strategic Work at TUBAF

Since my appointment, I have contributed to a wide range of strategic activities for the advancement of TU Bergakademie Freiberg and have often played a shaping role in these.

Since 2009, I have been involved in the conceptualization and application for a Resource Research Institute at the Freiberg location, which was founded in 2011. During its establishment phase from 2011 to 2014, I was responsible for the Processing Department. In this context, the preparation for EIT RawMaterials also took place, which began in 2012 and transitioned into the operational phase with a successful application in 2015. From 2015 onwards, I have been active in the Steering Committee of CLC East of EIT RawMaterials, serving as its chairman from 2015 to 2016 and thus also a member of the strategic management circle of EIT RM Materials at that time. As a consequence for TU Bergakademie, the Regional Center Freiberg (RCF) was established in 2016 as a central facility of the university with me as the founding director. The RCF represents the interface of the university, the Helmholtz Institute Freiberg, and the Saxon economy to EIT RawMaterials. During my time as Vice Rector for Structural Development, I was able to develop a digitalization strategy, which also processed the experiences made during the ad-hoc digitalization during the Corona period. In this context, I also initiated and conducted the Peer-to-Peer through the Stifterverband to continue the digital development of TU Bergakademie. A change in perspective was brought about through my further training as a Digital Change Agent through the HDS.

At the end of 2022, I resigned from the Rectorate as Vice Rector for Structural Development upon my appointment to the NFDI Expert Committee of the DFG. To continue the digital activities at the university, the role of Chief Officer TUBAFdigital was created, which I have held since then. In this role and with the support of the digitalization successes achieved in teaching until then, we were able to react quickly from 2022 onwards and set up a support program for Ukrainian universities so that Ukrainian students could access our digital teaching content. I am extremely pleased that TU Bergakademie was rated as "the most digitalized university" in Saxony in a 2024 survey by the UniNow portal.

In my work for the NFDI, I try to pave the way for data-driven science, particularly in engineering. This involves various aspects such as the generation of research datasets, their organization and exchange beyond the borders of the university landscape, their utilization and analysis, and of course the necessary skills among students and researchers.