Sub-project: Laboratory plant for energy-efficient oxygen separation using OSM pellets and water vapour circulation

Main project:

Development of an efficient oxygen separation process using ceramic pellets (HeatToO2)

| Project manager | Project manager | Project duration |

|---|---|---|

| Prof. Dr.-Ing. Tobias Fieback Dr.-Ing. Thomas Grab | M.Sc. Kabriil Khajryan | 1 March 2023 to 31 October 2025 |

Research topic

Oxygen is one of the most important chemical intermediates. In Germany, O2 production in 2022 amounted to approx. 6 billion m³ (i. N.). The steel industry is a major consumer of oxygen, with significant consumption also identified in oxyfuel processes.

Currently, most of the oxygen is produced by centralised cryogenic air separation plants and then distributed to end users. In the LTA, the air is cooled to around -185 °C (the condensation temperature of oxygen), which breaks down the air. However, centralised generation incurs transport and storage costs. For decentralised on-site generation of oxygen, PSA or VPSA (Vacuum Pressure Swing Adsorption) systems are currently the main option. However, these have a high electrical energy requirement.

An alternative to these fully developed methods is the use of perovskite oxides (e.g. BSCF - Ba0.5Sr0.5Co0.8Fe0.2O3-δ). These ceramic-based materials become oxygen-permeable at high temperatures (from approx. 700 °C) and an existing O2 partial pressure difference. This offers a wide range of possible applications, such as the utilisation of industrial waste heat from high-temperature processes, e.g. in steelworks, the glass and ceramics industries. By utilising waste heat, the perovskite oxides and necessary material flows are heated and oxygen is produced on site for in-house consumption.

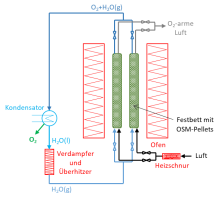

It is possible to produce the perovskite oxides in the form of MIEC membranes (MIEC: Mixed Ionic-Electronic Conductor) or as OSM pellets (OSM: Oxygen Storage Material). To realise the O2 partial pressure difference in the MIEC membranes, air flows on one side of the membrane. On the other side, either negative pressure is generated (vacuum process) or O2-free gases flow (purge process), e.g. He, CO2 and water vapour. With the purging process, the energy and cost-intensive vacuum pumps can be dispensed with. The advantage of water vapour over other O2-free gases is that oxygen can be easily separated from hydrogen by condensation. It is also possible to utilise the heat of condensation to re-evaporate the water. The MIEC membranes were investigated using water vapour as a purge gas in the "SemDa" project and a proof-of-concept of the process was demonstrated. However, the membrane tubes are very brittle and can break in the event of temperature jumps or frequent start-up and shut-down ramps. OSM pellets can therefore be more easily implemented in industry. The pellets are alternately circulated by air and water vapour. The oxygen is then adsorbed by the air flow, "stored" in the OSM pellets and desorbed by the water vapour flow. The water vapour is then condensed in the same way as with the MIEC membranes, separating the oxygen from the water vapour.

Subprojects

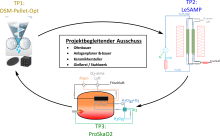

TP1: OSM-Pellet-Opt:

OSM pellet optimisation through material adaptation, production and characterisation (IKTS)

TP2: LeSAMP:

Laboratory plant for energy-efficient oxygen separation using OSM pellets and water vapour circulation. (TUBAF TTD)

TP3: ProSkaO2:

Process development and scaling of O2 separation using OSM (DBI)

Objectives of the LeSAMP sub-project

- Development of a laboratory plant as a demo plant

- Investigation of various test parameters (temperature as well as water vapour and air mass flow)

- Investigation of various pellet geometries

- Development of an energy-efficient heat management system to ensure the operation of the process through waste heat utilisation

- Determination of process-relevant key figures