The direct multi-element analysis of matrices that are difficult or impossible to break down, such as ceramics, semiconductor materials, oxides or carbonaceous materials (energy raw materials, graphites), is of great industrial relevance. Knowledge of the elemental composition of input materials is essential for their efficient energetic or material utilisation. When coal is burnt in power plants, the aim is to achieve the highest possible combustion chamber temperature in the boiler in order to maximise efficiency. However, the boiler temperature is limited upwards by the ash melting temperature of the coal mixtures used, which in turn is influenced by a number of main and secondary elements in the coal. It is therefore necessary to use methods with high dynamic analysis ranges in order to quantify major, minor and trace elements as simultaneously as possible in one measurement. Graphites, on the other hand, have a very wide range of applications in the high-tech industry, which makes knowledge of the trace elements they contain fundamental to the efficiency of the end product - for example in electronic components, batteries or supercapacitors (CDC, carbide derived graphite).

Various analysis methods are currently used to characterise such difficult matrices. The established methods are limited to very time-consuming analysis procedures due to the high preparative effort involved, which rules out in-process analysis. Necessary sample preparation steps such as ashing, microwave pressure digestion or wet chemical extraction are not only time-consuming and labour-intensive, they also often require highly pure and sometimes difficult-to-handle digestion chemicals (e.g. hydrofluoric acid).

The optimisation of analytical methods is therefore a fundamental starting point for increasing the efficiency of processes. With the further development of analytical methods, process-accompanying procedures in particular are to be created that enable rapid influence on the operating process and process control adapted to the feedstock quality. In particular, fast procedures are to be developed that provide additional information to the established analysis methods or combine them in one method.

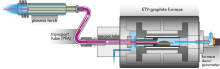

Direct solids analysis using ICP OES and -MS in combination with electrothermal vaporisation (ETV) and laser ablation (LA) makes it possible to analyse samples without bringing them into solution by means of the otherwise obligatory digestion. This means that the sample is not chemically altered or diluted prior to analysis and the risk of contamination and loss of analytes is minimised. However, this requires special sample feeding systems that transfer the solid samples into the plasma in a transportable form. This combines the advantages of ICP OES and -MS, such as high dynamic range and detection strength, with the aforementioned advantages of solid analysis. The coupling of solid sample feed opens up additional possibilities such as time-resolved simultaneous multi-element analysis during the thermal decomposition of the samples (ETV) or spatially resolved analysis (LA), but requires considerably more effort in the development of analytical methods.

Publications

- Bacquart, T.; Hassler, J.; Vogt, T. et al. (2017) ETV-ICP-OES: a useful technique for homogeneity study of trace element in metals - application to the homogeneity study of 23 elements in electrolytic copper. Accreditation and Quality Assurance 22:125

- Wolf, B.; Vogt, T.; Bauer, D.; Neuroth, M.; Otto, M. (2016) Die ETV-ICP OES als schnelle Multielementanalyse im Methodenvergleich. labor&more 1/2016

- Vogt, T.; Bauer, D.; Nennstiel, D.; Otto, M. (2015) Solid-Sampling Electrothermal Vaporisation Inductively Coupled Plasma Optical Emission Spectrometry for Direct Determination of Total Oxygen in Coal. Analytical Chemistry 87(20):10414-10420

- Vogt, T.; Bauer, D.; Neuroth, M.; Otto, M. (2015) Quantitative multi-element analysis of Argonne Premium Coal samples by ETV-ICP OES - A highly efficient direct analytical technique for inorganics in coal. Fuel 152:96-102

- Vogt, T.; Tesch, S.; Otto, M.; Hassler, J.; (2012) Trace analysis in silicon. Electrothermal vaporisation for direct solid analysis. GIT Labor-Fachz. 56(8):588-590

Cooperation partners

- RWE Power Ag

- LEAG

- HC Starck

- Heraeus

- TU Bergakademie Freiberg, IEC-EVT

- Skeleton

- Spectro Analytical Instruments

- Spectral Systems

- DBI Virtuhcon GmbH