Automation of networked machines in open-cast mining

Background

The trend towards automation in all areas of life continues. For example, efforts are also being made to automate working machines in the open-cast mining sector in order to reduce the amount of human labour required during operation. Digital, mostly decentralised systems are primarily implemented for automation. Expertise from several engineering and IT fields is required to enable the interaction of hardware and software from individual machines to entire machine groups.

Objective

The aim is to develop a methodology that can be used to automate working machines in open-cast mining. The focus is on the integration of embedded systems into existing structures, as well as the decentralisation of machine control and the associated increase in digitalisation and the degree of autonomy. A specific area of application is defined by considering the processes encountered in open-cast mining: the detection, extraction, transport and processing of material. To this end, a software architecture for the embedded area is being developed and implemented on a model. Other focal points include control technology for electronically commutated motors and networking, both internally via bus systems and externally via WLAN communication.

Optimised operational management of networked energy systems

Background

The switch to renewable energies is leading to an increase in decentralised energy systems, both commercial and private. At the same time, increased generation capacity must be maintained in order to compensate for volatile dips in renewable generation. This leads to an increased load on the grid due to possible power dips and load peaks, which cannot currently be compensated for by sufficient grid expansion.

Objective

The aim is to find suitable options (rule-based or algorithmic approaches) for the operational management of decentralised energy systems using the existing networking of the systems. The flexibility of the individual systems is utilised to ensure that operation is as grid-friendly as possible. This includes the provision of positive or negative balancing power as well as the offer to withdraw or store energy. The operation of the individual systems must take place within legal, economic and technical framework conditions and harmonise the interests of the system operator and grid operator.

Regional virtual power plant based on mini and micro CHP technology

Background

The subject of the investigations is the possible networking of decentralised generation structures, especially micro-CHP technology and electrical consumers in urban areas. The project focuses on detailed analyses of a regional network. Initially, extensive metrological analyses will be carried out on a laboratory scale. These focus on both thermal and electrical analyses, whereby the devices are examined in a virtual test environment that simulates the low-voltage grid. In a second step, numerical investigations are carried out under various operating conditions (building size, building type, user behaviour). In addition, control and optimisation strategies will be investigated in the network, which will be forwarded to the systems via securely encrypted communication. Finally, the realisation of a "regional virtual power plant" is to be implemented.

Objective

The aim of the project is to derive operating strategies for μ-CHP systems, both in the building and for the operator of a virtual power plant. Data acquisition, filtering and further processing are given high priority in the project. The investigations, especially on the "virtual power plant", should help to better control the highly fluctuating generation of electrical energy (based on wind and photovoltaics) to be expected in the future.

Monitoring and efficient control of small energy systems

Background

The resource-saving technology principle of combined heat and power (CHP) is used in micro block-type thermal power stations (MBHKW). These are "mini power plants" for private households that use a petrol engine to convert natural gas into heat and electricity. The electricity can either be consumed in the household or fed into the energy grid for a fee.

Objective

Within the scope of this research project, monitoring software is to be designed for MBHKWs that send their measurement data (temperatures, gas consumption, engine speeds, etc.) to a central database, which is later accessed by a Java server. The clients connect to the server and thus have the possibility to visualise and analyse the temporal behaviour of the systems.

When MBHKWs are considered as a "virtual power plant" in conjunction with wind or PV, their group dynamics are in the foreground. In order to achieve efficient overall utilisation of all systems, a central computer must monitor and control all demand and production. It decides which plants produce how much electricity and when, or whether electricity is overproduced and fed into the grid at peak demand times for a higher fee. As a virtual power plant can only function if there is a financial incentive for each participant in this network, this leads to a multi-stage, discrete optimisation problem with numerous constraints, which must be solved in real time using intelligent control algorithms.

Automation of decentralised energy systems

Background

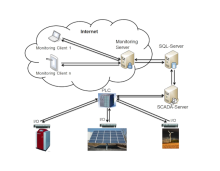

This research project involves controlling a system with three energy suppliers that send their information to a central database server via the internet. The systems considered here are combined heat and power plants (CHP), wind energy systems and photovoltaic systems. The control system consists of three levels:

- Information level (control level): At this level, the central control system makes the most important decisions for the entire system. Based on higher-level electrical requirements, control commands are calculated either manually or by an intelligent control algorithm. These decisions are made on the basis of the current measured values from the system sensors. A SCADA system (Supervisory Control And Data Acquisition) is used for data acquisition and storage.

- Control level: This level represents a hybrid process between the central control system and the device-internal controls. The controller of the central control system is realised by a PLC (programmable logic controller).

- Device Level: This level contains all hardware-related sensors and actuators.

Objective

The aim is to switch the energy systems on and off at set times using a complete control system (Distributed Control System DCS). The overall intelligent energy system created in this way represents an alternative to previous conventional solutions.

CO2 measurement and monitoring system

Background

The use of CCS (carbon capture and storage) technology offers a promising alternative for reducing the concentration of carbon dioxide in the atmosphere. With this bridging technology, the CO2 contained in flue gas, which is produced during combustion processes in power plants, among other things, is permanently stored in geological underground formations. For safety reasons, the impermeability of the underground storage facilities must be permanently monitored and any leaks detected.

Objective

The aim of the research project is to develop a monitoring system with which the CO2 concentrations in the ground above the storage area can be automatically recorded, evaluated and visualised. Modified standard measurement procedures are combined with state-of-the-art sensor technologies (intelligent sensors, multi-sensor systems) and measurement methods.

Automation of diffusion experiments in metallic melts

Background

The properties of metallic materials are significantly influenced by the melt and the solidification process. For the best possible material design, the physical processes must be precisely described and modelled. Diffusion in the melt has a significant influence here. As convection makes it difficult to determine the diffusion coefficients, experiments are to be carried out without this influence in the Material Science Laboratory (MSL) on the International Space Station (ISS). As the exact investigation of the diffusion process requires an exact temperature field, a precision control system is being developed that uses an exact model of the system. For this purpose, two- and three-dimensional semi-discrete FD models are being developed and their parameters identified.

Automation of digital printing lines

Background

Modern digital production printing is characterised by the fact that there is no printing form (master) and it is therefore possible to print each page differently. The variable costs per page are typically higher than with traditional printing, which is why digital printing is particularly interesting for short-run scientific prints, invoices or personalised advertising. Production often takes place in printing lines that contain the necessary finishing equipment such as folding, stitching, binding or cutting machines in addition to printing presses.

Problem definition

Unfortunately, the degree of automation of industrially used digital printing lines lags far behind the technical possibilities known today, although there are strong arguments in favour of better integration of the devices from a business perspective. Ten years ago, an industry consortium developed a manufacturer-independent automation concept based on IEEE-1394 (Firewire), which was unable to establish itself in practice despite the lack of alternatives.

Solution approach

The specially developed automation concept provides for the parallel use of standard Ethernet and CAN bus. Furthermore, a new type of remote control concept was developed that can be transferred to other areas of automation and has clear advantages over known solutions. Its strengths lie in the user-friendly operation of production lines, whereby no individual integration effort is required for new device combinations. A migration solution based on an embedded Linux was developed to enable mixed operation of devices with previous and new communication solutions within a printing line and to test the concept as part of a reference implementation. The hardware and software used was designed in-house and has proven its worth.

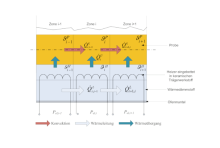

Modelling and control of high-temperature processes in multi-zone furnaces

Background

Multi-zone furnaces play an important role in materials science, both in single-crystal growth using the Bridgeman, gradient freeze or floating zone methods, as well as in the investigation of diffusion processes. A multi-zone furnace consists of approximately four to seven heating zones joined together. For precise temperature control, each zone can be controlled separately and contains at least one temperature sensor.

For optimum cultivation results, high temperature stability of up to ± 0.01 K at 1600 °C is required. The mutual influence of the zones is a problem here. With an exact system model, model-based predictive controllers and optimum controllers can be developed and parameterised.

Internet-based monitoring and control of automation processes

Background

Software systems for solving automation tasks are often developed as single-purpose systems and are difficult to adapt to other problems. However, numerous functionalities (e.g. visualisation of measured values, device configuration, user administration) are always required. Application frameworks offer the possibility of implementing these core functions in isolation from the actual problem. The JAVA framework OMaCS (Online Management and Control System) was developed for the creation of internet-based monitoring and automation systems. Combined with a plug-in concept, the individual applications can be expanded and adapted as required.

The basic framework offers the storage of user and measurement data in a database as well as a client-server architecture, which makes it possible to view the data via the Internet using a PC or mobile phone. Basic aspects of data security (e.g. access protection, encryption) also play an important role here.