Toroidal experiments

Toroidal HP/HT experiments could be performed in a 1000 T hydraulic press (Voggenreiter Sondermaschinen GmbH, Mainleus, Germany) at the Freiberg-High-Pressure Research Center (FHP). There are four steps on the basis of time quantum:

Toroidal cell assembling

Pressure medium cell which contains the furnace should be built up firstly. The furnace includes resistive heater and furnace wall – thermos insulator.

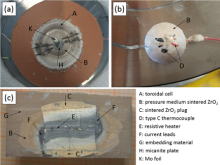

The example of the brief photo introduction of toroidal assembling before HP/HT experiment is shown in Figure 1.

A type C thermocouple is used to detect the temperature near the center of the resistive heater. Copper coils are used to protect the thermocouple wires in the extrusion zone of the toroidal assembly cells. After the toroidal cell is built up, they are assembled in the center of the toroidal apparatus, surrounded by two identical coaxial mutually compress facing plates.

Compressing

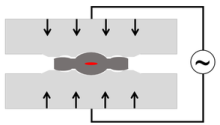

Compressing progress could be controlled up to 12 GPa. The schematic illustration of toroidal HP/HT compressing is shown in Figure 2

Sintering

In the toroidal HP/HT experiments, both alternating current and direct current could be supplied. In AC applying, power is controlled by stepwise increasing. In DC applying, power is controlled by the program. Temperature is measured during sintering. All the electrical data are fed into the data logger to record the sintering process.

Preparation for characterization

After shutting off the power supply, the experiments cool down naturally, followed by slow decompression. In order to characterize the performance of the resistive heater, the sintered toroidal assembly should be prepared. Figure 3 shows the overview of the toroidal cell after HP/HT sintering.

(i) Open the HP/HT apparatus and take the sample out (c. f. Figure 3 (a));

(ii) Clear off the toroidal parts and leave the furnace (resistive heater and insulation walls) (c.f. Figure 3 (b));

(iii) Embed, incise (c. f. Figure 3 (c)) and polish the sample to get a smooth cross-sectional surface.