Metallic Materials Technology

Shape the Future of Materials Engineering

The Master’s programme in Metallic Materials Technology (MMT) at TU Freiberg equips students with advanced knowledge and practical skills in the field of metallic materials. Whether you have a background in mechanical engineering, materials science, or a related discipline, this programme offers a unique opportunity to specialise in cutting-edge technologies that are driving innovation in automotive, aerospace, green energy, and advanced manufacturing industries.

Join a diverse international community, deepen your expertise, and position yourself for a successful career in materials engineering.

The MMT programme builds upon a Bachelor’s degree in mechanical engineering, materials science, or metallurgy and aims to provide students with advanced expertise in metallic materials. The curriculum focuses on both theoretical and practical aspects, combining technical skills with a scientific approach to solving real-world challenges.

Students can tailor their studies by choosing from four specialisations, each designed to provide in-depth knowledge and industry-relevant skills. The programme is conducted entirely in English, attracting a diverse and international student body.

The MMT programme spans four semesters (two years) and requires a total of 120 ECTS credits for graduation. The curriculum is designed to provide students with:

- Core Subjects: Materials science, mechanical properties, and manufacturing processes.

- Elective Modules: Flexibility to tailor the education to individual career goals.

- Master’s Thesis: A research project addressing real-world industry challenges.

- Specialisation Tracks: Students can choose one of the following four specialisations to align their studies with their interests and career aspirations.

Please note that this is an English-language Master's degree programme. Applications for the summer semester are made online via the university portal and are possible from 1 July to 15 October (recommended). For the winter semester, application is also possible online via the university portal from 1 January 1 to 15 April.

Specializations

Foundry Technology

This specialisation focuses on the fundamentals and advanced aspects of modern casting processes. Students will learn about:

- Moulding materials, binders, and core-making processes.

- The metallurgy of ferrous and non-ferrous casting materials, including melt treatment and analysis techniques.

- The operation of melting furnaces and quality assurance in foundry processes.

- Post-treatment of castings, surface engineering, and defect prevention strategies.

- Applications in the automotive, aerospace, and machinery industries, where high-performance castings are crucial.

Metal Forming

Metal forming covers the transformation of metallic materials into semi-finished and finished products through various techniques. This specialisation includes:

- Advanced rolling, forging, and extrusion technologies.

- Theoretical and experimental analysis of metal deformation behaviour.

- The influence of microstructural properties on mechanical performance.

- Numerical simulation and process chain optimisation.

- Applications in automotive, construction, and aerospace sectors, where precision-formed metals play a vital role.

Non-Ferrous Metallurgy

Focusing on the production and recycling of non-ferrous metals such as aluminium, copper, and rare earths, this specialisation includes:

- High-temperature, hydrometallurgical, and electrochemical processes for extracting and refining metals.

- Advanced recycling technologies to recover valuable metals from batteries, electronic waste, and industrial by-products.

- Sustainable production techniques aimed at minimising environmental impact.

- Applications in electronics, renewable energy, and battery technology, where lightweight and high-performance metals are essential.

Steel Production

This specialisation provides expertise in the entire steelmaking process, from raw material processing to advanced refining techniques. Key topics include:

- Primary and secondary metallurgy, including decarburisation and alloying.

- Clean steel production, energy efficiency, and sustainable practices.

- Structural and mechanical properties of steel for construction and transport applications.

- Circular economy strategies for reducing emissions and improving resource efficiency.

- Applications in infrastructure, automotive, transportation, and green energy.

- Faculty

-

Faculty of Materials Science and Technology (Faculty 5)

- Degree

-

Master of Science (M. Sc.)

- Standard period of study

-

4 Semester

- Part-time possible

-

No

- Start of studies

-

Winter semesterSummer semester

- Admission requirement

-

- Bachelor's degree with a focus on materials science or materials technology (at least 6 semesters) or an equivalent degree in the field of metallurgy, materials engineering, or another related discipline

- A 12-week industrial internship is required. It is recommended to complete all or part of the internship before starting the degree program. However, missing internship periods can also be made up during the degree program, e.g. during the lecture-free period or until the topic of the Master's thesis is issued. The internship can be completed in various companies (materials engineering, materials science, metallurgy, or related fields). The certificates must show which activities were carried out

- Qualification assessment procedure

Language skills:

- English language skills (TOEFL at least 90 internet-based tests, IELTS at least 6.5 or equivalent language certificate) - this does not apply to applicants whose national language is English.

- Course language

-

English

Graduates of the MMT programme have access to diverse career paths across various industries. Potential roles include:

- Iron and Steel Industry: Production, quality control, and process optimisation.

- Foundry Industry: Casting processes, mould design, and quality management.

- Metal Forming Technology: Developing manufacturing processes for critical applications.

- Mechanical Engineering: Applying metallurgical knowledge to machine and component design.

- Refractory Industry: Innovating high-temperature-resistant materials.

- Metal Processing Industry: Enhancing efficiency in materials production.

- Process Development: Driving innovation in metallurgical processes.

- Technical Sales and Consulting: Advising clients on material applications and performance.

- Research Institutions: Conducting cutting-edge research in universities and industry labs.

Why Choose the MMT Programme?

Studying at TU Freiberg offers several unique advantages:

- Comprehensive Education: A well-structured curriculum covering materials processing, sustainability, and business management.

- Global Career Prospects: Graduates are highly sought after in industries such as mechanical engineering, metallurgy, and renewable technologies.

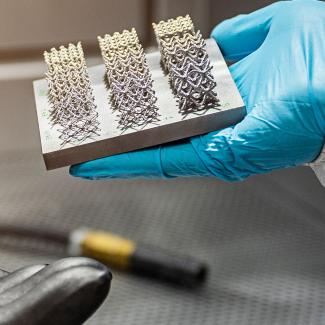

- State-of-the-Art Facilities: Access to modern laboratories and cutting-edge equipment provides students with a practical, hands-on learning experience.

- Affordable Living: Freiberg offers significantly lower living costs compared to larger cities like Berlin or Munich, making it an attractive destination for international students.

- Flexible Career Paths: From research and development to technical consulting and production management, the MMT degree opens doors to numerous opportunities.

Why Study at TU Freiberg?

Located in the heart of Europe, TU Freiberg is renowned for its excellence in materials science and engineering education. Students benefit from:

- Affordable living costs, making it an attractive destination for international students.

- State-of-the-art facilities, including specialised labs for materials testing and processing.

- Strong industry connections, ensuring access to networking events and career support.

Join our vibrant community and take the next step in your engineering career!

Student Testimonials

Hear from our students and graduates about their experiences in the MMT programme:

"Pursuing the Master’s programme in Metallic Materials Technology at TU Freiberg has been an incredible experience. The programme offers diverse specialisations, allowing students to deeply explore their field of interest. The skills and knowledge I’ve gained throughout the programme have significantly deepened my understanding of metal forming, allowing me to approach my thesis topic at one of Germany’s leading metal companies with confidence and a solid foundation."

— MMT Graduate

"The hands-on learning opportunities, combined with access to state-of-the-art facilities and guidance from expert faculty, have greatly enhanced my understanding of materials science. The programme provides a supportive academic environment that encourages growth and fosters a deep understanding of complex topics. It has opened up numerous career opportunities, preparing me for exciting roles in both industry and research."

— Current MMT Student

Take the Next Step in Your Career

With the MMT programme at TU Freiberg, you can develop the technical and managerial skills needed to thrive in the rapidly evolving materials industry. Whether your goal is to work in research and development, technical sales, or production management, this programme equips you with the tools for success.

Apply now and become a leader in materials technology!