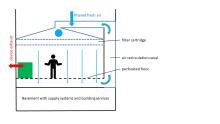

Principle of a clean room

Supply and disposal systems are located on the lowest level, the actual laboratory area with air recirculation in the floor is in the centre and the air conditioning and air purification systems are on the upper level. The filter technology ensures that impurities are immediately removed from the air. A low-turbulence displacement flow from top to bottom is utilised for this purpose. Together with multi-stage filtration and a high air flow rate, cleanliness classes between 5 and 7 [ISO EN DIN 14644] are achieved at a constant temperature and humidity, depending on the laboratory area. The Central Cleanroom Laboratory (CCL) has five cleanrooms of class ISO 5 (class 100 according to FS 209), one of class ISO 6 (1000) and two of class ISO 7 (10,000). In an ISO 5 class cleanroom, no more than 3500 particles greater than or equal to 500 nm may be present in one cubic metre of air, and only 29 particles greater than or equal to 5000 nm. This places high demands on the people working there and the equipment and aids used with regard to minimum particle emission.