Research focus of the professorship for Modeling of Thermochemical Conversion Processes

Image

MTK

Modelling, development and optimization of high-temperature processes

- Integration of electricity from renewable energies in high-temperature processes, e.g. via plasma technologies

- Hydrogen and ammonia integration in high-temperature processes

- entrained-flow, fluidized-bed and fixed-bed processes for the conversion of biomass, residual materials and conventional carbon carriers

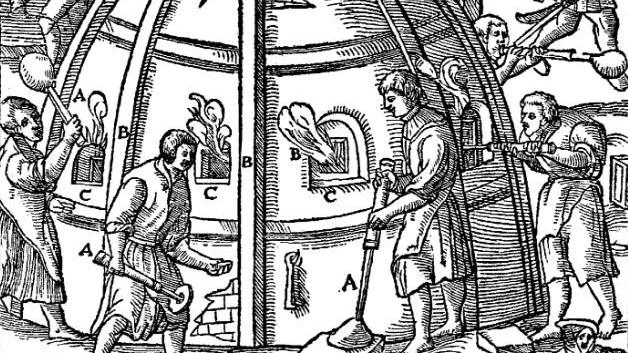

- Converters and furnaces for the recycling of non-ferrous metals (submerged lance processes, melting furnaces, casting processes)

- Blast furnaces and glass melting processes

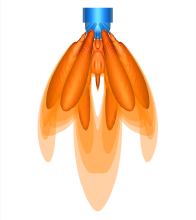

High-pressure partial oxidation of gaseous and liquid feedstocks

- Catalytic and non-catalytic reforming

- Biogas, bio-oil, lean gases, process gases, natural gas, refinery residues

- Process development and optimization

- Burner development

Image

MTK

Accelerated process optimization

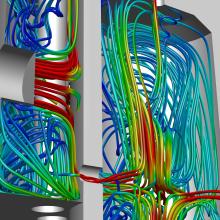

- Development of reduced models for accelerated process modeling

- Automated process optimization

- Multi-criteria, multi-parameter optimization

Model-based laboratory

- Model-based design and development of new test benches and optical measuring systems

- Model-based test design and evaluation

Modeling and analysis of material conversion processes on the microscale

- Mass and heat transfer at gas-solid and gas-liquid interfaces

- High-resolution calculations of reacting particles including pore development and shape change

- Drying, pyrolysis, heterogeneous reactions

Projektvorhaben der Professur Modellierung von thermochemischen Konversionsprozessen

Image

IGT

QualiGlas

Prädikative Bewertung der Glasqualität bei zukünftigen Technologien zur Nachhaltigen, CO2-emissionsneutralen Glasherstellung

Image

MTK

H4Cu

Erdgassubstitution durch Wasserstoff in der Kupferhalbzeugherstellung

Image

MTK

GreenTBRC

CO2-freies Recycling von Nichteisen-Metallen

Image

MTK

GlasLAB - ad vitam

Design, Aufbau und Inbetriebnahme eines innovativen Laborschmelzofens für Glas