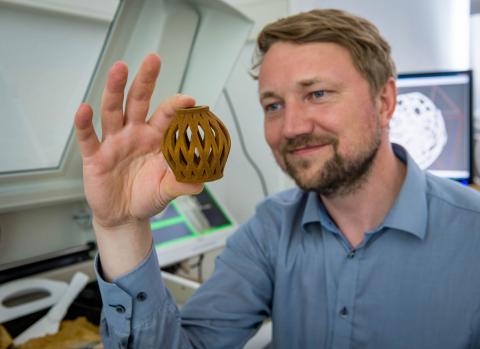

Additive Fertigung (Technologie, Material, Design)

The key technology of Additive Manufacturing combines numerous innovative processes that make it possible to manufacture complex, sophisticatedly designed products directly on the basis of computer data. Often referred to as "3D printing", these technologies work layer by layer and require neither moulds nor specific tools. They are very resource-efficient because they only use material where it is needed in the end product. In particular, they offer more freedom for product design, making completely new designs and constructions possible. In addition to technical applications, they are therefore also very popular in the fields of art, design and architecture.

The degree programme combines all aspects of additive manufacturing, taking into account component development and product design, additive manufacturing technology as well as materials and their production:

You will learn about the various additive manufacturing processes in detail, the selection and technology of which depends on the material, component size and product requirements. The materials considered include metallic materials as well as ceramics, glass and building materials, but also plastics and renewable raw materials. As one focus of additive manufacturing is on particle-based processes, particle technologies such as crushing and sieving are also considered.

Development and construction are considered both from the perspective of lightweight construction and from the perspective of design, as additive manufacturing enables functional integration with simultaneous, appealing product design. Aspects of design and artistic creation are combined with the technical aspects of product development.

The degree programme offers a holistic view of additive manufacturing. Career opportunities therefore lie in various industries and along the entire development chain from raw materials to product design to the manufacturing process, right through to overarching tasks.

Course of study

The first 4 semesters comprise an orientation and aptitude phase with application-specific modules as well as the engineering, mathematical and scientific foundations. The 5th and 6th semesters allow students to choose from four specializations that deal with materials, product development/design and particle production and processing for additive manufacturing. The 7th semester includes a specialist internship in industry and the Bachelor's thesis.

Specialisation

Engineering design in additive manufacturing

You will learn in depth about the development and design of additively manufactured products.

Mechanical process engineering

You will learn in depth about the production and further processing of particle raw materials for additive manufacturing.

Ceramics, glass and building materials

You will gain in-depth knowledge of additive manufacturing processes and material properties for use in the ceramics, glass and building materials industries.

Metallic materials

You will gain in-depth knowledge of additive manufacturing processes and material properties with a focus on metallic materials.

- Faculty

-

Faculty of Mechanical, Process and Energy Engineering (Faculty 4)

- Degree

-

Bachelor of Science (B. Sc.)

- Standard period of study

-

7 Semester

- Part-time possible

-

No

- Start of studies

-

Winter semesterSummer semester

- Admission requirement

-

Abitur or subject-specific higher education entrance qualification or an entrance qualification recognized as equivalent

Language requirement

- Application: with at least B1 level German

- Admission to the degree program: with C1 level German (e.g. DSH-2)

- language courses and DSH exam at TUBAF

- Prep Courses (Studienkolleg)

- Course language

-

German

Additive manufacturing has a wide range of applications in all industries and is already being used very successfully, e.g. in:

Vehicle construction and aviation industry

Development and manufacturing industry

Mechanical engineering

Development or manufacturing technology

Raw materials industry

Particle production for additive manufacturing

Medical technology

Development or manufacturing technology

Jewellery and arts and crafts

Design or manufacturing technology

Requirements

Admission requirements

Abitur or subject-restricted higher education entrance qualification or an entrance qualification recognized as equivalent

Language skills

A German language level of at least B1 is required for the application. Proof of C1 level German (e.g. DSH-2) is required for admission to the degree program. TUBAF offers preparatory intensive German courses.

Language courses and DSH examination at TUBAF Studienkolleg for international applicants

The degree program can also include modules that are offered in English. A minimum language level of B2 is recommended for these modules.

A 6-week basic internship is required for this degree programme (30 working days). Completion or partial completion before the degree programme (after the Abitur) is recommended. The internship can also be completed during the degree programme. Requirements for the basic internship can be found in the adjacent download. Dr Andrea Dög will be happy to answer any questions you may have (see the box on the right "Specialist advice").

Personal Requirements and Interests

- Interest in construction, design and digital processes

- A desire for interdisciplinary knowledge

- Enjoy the application and further development of state-of-the-art technologies

Suitable Master's Degree Programs at TUBAF

The Master's degree programme "Additive Manufacturing" offers the logical continuation of the Bachelor's degree.

With the Bachelor's degree Additive Manufacturing: Technology, Material, Design, however, you can also transfer directly to other Master's programmes at TU Bergakademie Freiberg, e.g. Master's Mechanical Engineering, Process Engineering, Ceramic, Glass and Building Materials Technology and Vehicle Construction: Materials and Components.

Rankings