Verfahrenstechnik und Chemieingenieurwesen

Process engineering and chemical engineering ("VTC" for short) deal with all processes in which substances are changed in terms of composition, type or properties. They use mechanical, thermal, chemical or biological processes.

The electronic materials in your mobile phone, tablet, laptop or PC were obtained from raw materials using process engineering processes. The plastics, paints, varnishes and foams that surround you have been produced from basic chemicals using technical processes. The food and luxury foods you eat and the pharmaceuticals you consume are produced from natural substances using technical processes. Hydrogen, the energy carrier of the future, is produced by means of technical processes. The greenhouse gas carbon dioxide is "captured" by means of technical processes and deposited in landfills or converted into chemicals, fuels and products by means of technical processes. Municipal and industrial residues (waste), wastewater and exhaust air streams are treated, purified and/or recycled using process engineering processes. This list could go on and on. You will have realised by now that the VTC represents highly relevant future technologies for our supply of a healthy environment, energy, basic chemicals and food, and that the areas of application for a graduate of the VTC are almost endless.

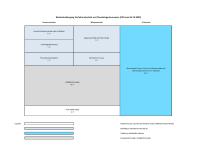

In the three-semester Master's degree programme in VTC, you have to earn a total of 90 credit points (CPs). 30 CPs are allocated to the Master's thesis and 28 CPs to the five compulsory modules (Environmental Process Engineering, Technology Assessment, Process Chain Simulation, Apparatus Engineering and Plant Design and Chemical Processes). You can choose from two categories for the remaining 32 CPs. In the compulsory elective module category, you must earn 26 CPs. Here you can choose according to your interests from a selection of at least 17 compulsory elective modules. In order to achieve the 26 CPs, you must take around five of the 17 modules on offer. With the free elective modules, you are completely free to choose from all the modules offered at TUBAF.

Thanks to the wide range of electives on offer, you are free to take many modules from one area of VTC if you would like to specialise in one discipline of VTC, or to spread the modules across the various disciplines of VTC if you would prefer a broad education.

The Master's degree programme in VTC no longer teaches the fundamentals of natural sciences, engineering and process engineering. These are a prerequisite and the scientific training of future graduates in the Master's degree programme in Process Engineering and Chemical Engineering is based on these.

What else needs to be said:

-No more than five examinations per examination period, usually only four examinations per examination period. You don't have to rush from exam to exam! You have the time and opportunity to really get to grips with the material and learn it for long-term memory.

-individual options by choosing compulsory elective modules from a predetermined module catalogue and by choosing free elective modules. You can develop flexibly according to your engineering interests and you also have the opportunity to think outside the box

The Master's degree programme provides excellent preparation for future job profiles in industry and science. It offers you the opportunity to develop your individual interests over the course of the programme.

Please note that this is a German-language degree program. At TUBAF we offer a variety of English Master's degree programs. Click here for an overview.

- Faculty

-

Faculty of Mechanical, Process and Energy Engineering (Faculty 4)

- Degree

-

Master of Science (M. Sc.)

- Standard period of study

-

3 Semester

- Part-time possible

-

No

- Start of studies

-

Winter semesterSummer semester

- Admission requirement

-

Professionally qualifying university degree in a related subject with a standard period of study of at least 7 (6 with conditions) semesters

Language requirement

- Application: with at least B1 level German

- Admission to the degree program: with C1 level German (e.g. DSH-2)

- language courses and DSH exam at TUBAF

- Course language

-

German

Research and development as well as project planning, operation and maintenance of process engineering equipment and plants, including in the chemical industry, energy industry, battery (recycling) industry, ceramics, glass and building materials industry, mining and processing, wastewater treatment, waste disposal and treatment, air pollution control, food industry, heating and air conditioning technology, biotechnology, mechanical and plant engineering in:

- Management and logistics

- Engineering offices

- Teaching and research: e.g. university, Fraunhofer Society, Max Planck Institutes

- Public sectore.g. university, Fraunhofer Society, Max Planck Institutes

- Public service: e.g. authorities, TÜV, local authorities, utilities and waste disposal companies, municipal utilities

- Business and professional associations, consultancy

- Professional activity: e.g. appraiser, industrial consultant, patent attorney