Ongoing projects / Laufende Projekte

A selection of ongoing projects is listed below

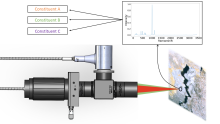

Development, characterization and exploitation of a Spectro-Optical method for the simultaneous measurement of composition and density of the coexisting phases of vapor/liquid-equilibria at elevated temperature and pressure (DFG)

The objective of the project is the development of a non-invasive optical measurement technique for the simultaneous determination of the densities and compositions of saturated vapor and liquid phases of binary and ternary vapor/liquid-equilibria (VLEs) at elevated pressures and temperatures (up to and ). Due to the availability of reference data (density and composition) at few elevated pressures and temperatures from literature, the binary “test-systems” will be composed of organic solvent (ethanol, acetone, ethyl acetate) plus CO2 and the ternary mixtures will additionally include water.

The objective will be reached by combining a self-engineered Raman spectroscopy technique (already existing and established) for composition measurements with a to-be-developed light barrier technique for the measurement of the volume flow rates of the two coexisting phases in a pressure and temperature resistant microfluidic glass capillary. The densities of the phases are then deduced from their compositions (obtained via Raman) and their volume flow rates (obtained via light-barrier technique).

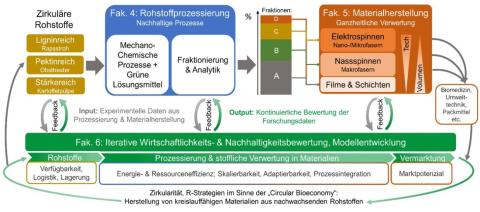

BIOWIN: Added value from biomass through integrative upcycling strategies (ESF)

The BIOWIN junior research group is funded by the European Social Fund (ESF) and the Free State of Saxony (Saxon State Ministry for Science, Culture, and Tourism (SMWK)) and addresses key challenges for a sustainable bioeconomy, particularly in rural areas. The aim of the project is to upgrade previously underutilized biogenic residues from agriculture and forestry and convert them into innovative, polymer-based materials. Various processes of mechano-chemical raw material processing and fractionation as well as fiber production are used to enable the highest possible quality use and holistic utilization of the biomass.

Detailed information on the ESF junior group "BIOWIN" and the joint partners are available at ->Website

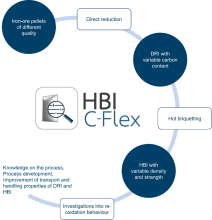

HBI C-Flex: Reoxidation behaviour and stability of direct reduced and hot briquetted iron with variable iron and carbon content to promote safe handling and transport for a future decarbonized steel production (EU-RFCS)

According to the green deal of the European Union the steel industry has to decrease its greenhouse gas emissions until 2030 by 30 % and until 2050 by 100 %. HBI C-flex supports the clean steel breakthrough technologies by demonstrating the direct reduction of iron ore of different quality, hot briquetting of the direct reduced iron (DRI), and investigation into the re-oxidation behaviour of the hot-briquetted iron (HBI). In the project, even the carbon content of the DRI will be reduced down to zero, as the direct reduction with H2 will change the carbon content of the DRI which additionally affects the briquetting behaviour. Consistently, strategies for safe handling and storage will be defined.

Within the project, ITUN covers the systematic investigations into hot briquetting of the DRI in laboratory scale by using a hydraulic piston press to ensure the independent variation of the relevant briquetting parameters.

HBI C-flex is funded by the European Union (Grant agreement ID: 101112479). Besides this public funding, the activities are co-financed by several industrial partner. We are very much grateful to the funding body and the contributing industrial partners for financing this project.

Detailed information on “HBI C-Flex” are available at ->Website of "HBI C-Flex"

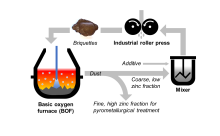

Sub-project of SusMet4Planet: Sustainable processing of solid residue streams (Austrian Funding Bodies)

The COMET competence center “K1-MET” focuses on research on “Sustainable Digitalized Metallurgy for a Climate Neutral and Resource Efficient Planet (SusMet4Planet)”. The competence center is collaborating closely with the Austrian steel industry for many years. “SuSMet4Planet” is running from July 2023 to June 2027 as follow-up to former funding periods.

Within the SusMet4Planet-Project, ITUN is involved in the sub-project 1.6 “Sustainable processing of solid residue streams”. To reach a sustainable steel industry, circular economy is one of the important pillars. Fine-grained dusts from iron and steelmaking represent secondary resources with considerable amounts of valuable metals – partly already in its metallized form – inducing the necessity of reusing valuable metal fractions internally (in the steelmaking process) and externally. ITUN will investigate mechanical processing (agglomeration) of metallurgical residues. A concept for Basic Oxygen Furnace (BOF) dust briquetting to produce stable briquettes for internal use should be elaborated within this work package.

The COMET Centre is funded within COMET – Competence Centers for Excellent Technologies – by the Austrian Federal Ministry for Climate Action, Environment, Energy, Mobility, Innovation and Technology; the Austrian Federal Ministry for Labor and Economy as well as the co-financing federal provinces Upper Austria, Styria and Tyrol. The COMET program is supervised by the Austrian Research Promotion Agency (FFG). Besides this public funding, the sub-project activities are co-financed by the industrial partner voestalpine Stahl GmbH Linz. We are very much grateful to all funding bodies and, especially, voestalpine Stahl GmbH for financing this project.

Detailed information on “SusMet4Planet”, former funding periods as well as K1-MET are available at ->Website of "K1-MET"

CBPBRecyc4Level: Development of a building material granulate as a floor leveling and insulating material for the valuable recycling of cement-bonded particle boards (AIF-ZIM Project)

The disposal of waste resulting from the production and processing of cement-bonded particle boards (CBPB) and their dismantling has followed so far the linear economy and currently ends mainly in above-ground building material landfills.

By reprocessing CBPB waste and producing new, refined products, landfill volume can be saved, as well as natural raw materials, CO2 emissions and energy. Therefore, the project aims to identify suitable recycling routes for CBPB residues or CBPB dust. A dry leveling fill should be created to level the ground for the renovation of old buildings and new buildings, which consists exclusively of secondary building material residues. Initially, CBPB residues and CBPB dust, and in the future also other building material waste, will be reprocessed. The target product should have a defined grain shape and grain shape distribution so that the individual grains wedge together when distributed on the surface in such a way that the surface cannot sink in later-on, especially under loading.

The focus at the ITUN is on the development of process and machine technology parameter sets for the production of granules that meet the requirements for the dry leveling fill depending on the residual material flows.

The project was started on December 2023 as a joint project between the Bausal GmbH and ITUN. We thank the Federal Ministry for Economic Affairs and Climate Protection (BMWK) as part of the “Central Innovation Program for SMEs (ZIM)” for funding this project.

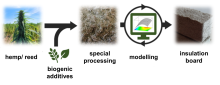

Zukunft Bau: Development of a correlation model for the production of insulation boards from plant residues (BBSR Project)

Since November 2023, the project “Development of a correlation model for the production of insulation boards from plant residue” has been running at ITUN.

The focus is on the utilisation of currently unused plant residues for the material usage in the construction industry, in this case as insulation material.

The portfolio of available insulation materials is currently dominated by synthetic or mineral materials, such as glass or mineral wool. Natural insulation materials are available to a much less extend and are often wood-based. At the same time, there is a large number of annual plants that are not fully utilised, such as hemp or reed.

Utilising crops for building materials often requires complex processing, including several mechanical disintegrations, additives and to the material adapted parameters. This study aims to find optimal parameters for creating a usable building material while avoiding the use of synthetic binders commonly found in such materials. Instead, leaves come to action for the first time, primarily to improve biological stability. All relevant experimental data and all effects to the insulation blanket will be combined in a mathematical correlation model. In addition to an improved understanding of the process, it should be possible to produce insulation material with optimized properties. This project is worked on by ITUN and its project partner Lausitzer Technologiezentrum GmbH.

We thank the Federal Institute for Research on Building, Urban Affairs and Spatial Development (BBSR) on behalf of the Federal Ministry for Housing, Urban Development and Building (BMWSB) for funding this project in the framework of “Zukunft Bau”. Further information can be found at ->Website of "Zukunft Bau"

A filmic project summary can be found here ->Project Film

MINOSENS: Wegbarmachung der Ramanspektroskopie zur Quantifizierung von Minoritätenspezies im (sub)‐ppm Massenanteilsbereich in wässrigen Lösungen ohne Probenvorbereitung (BMBF Projekt Photonikforschung)

Gefördert vom Bundesministerium für Bildung und Forschung im Rahmen des "Forschungsprogramms Quantensysteme (Projektnummer 13N16761)" ->zum Projektsteckbrief auf der BMBF Webseite

Paper zu aerogelbasierten Fluidlichtleitern

Motivation

Der Nachweis von Schadstoffen in Abwässern, von Düngemitteln im Trinkwasser oder von Biomarkern in medizinischen Proben ist für Mensch und Umwelt von wichtiger Bedeutung. Gängige Analyseverfahren sind jedoch zeitaufwändig. Effizientere Verfahren, die häufigere und kostengünstigere Analysen ermöglichen, sind gefragt. Besonders effizient sind Verfahren, die schnelle Messungen ohne Probenvorbereitung in einem einzigen Gerät ermöglichen.

Ziele und Vorgehen

Ziel ist die Entwicklung eines Analyseverfahrens, das in situ und ohne Probenvorbereitung die Konzentration einer wässrig gelösten Substanz misst, deren massenbezogene Konzentration im Bereich von einem Milliardstel (parts per billion, ppb) liegt. Verwendet wird hierzu die stimulierte Raman‐Spektroskopie (SRS): Die flüssige Probe wird mit Licht bestrahlt, das an der Probe gestreute Licht detektiert und sekundenschnell analysiert. Dabei erfolgt die Messung nicht in einem normalen Glasgefäß, sondern im Inneren einer mit Gel gefüllten Kapillare. Die wässrige Probe durchströmt das Gel. Die nachzuweisende Substanz wird aus der Lösung selektiv adsorbiert und so im Inneren des Röhrchens akkumuliert. Gel und wässrige Probe leiten außerdem das für die Raman‐Spektroskopie erforderliche Licht über die Länge der Kapillare (Lichtwellenleitung).

Innovation und Perspektiven

Durch Kombination der Vorteile von SRS, Lichtwellenleitung und Analyt‐Akkumulation soll Nachweisgrenze bis in den ppb‐Bereich gesenkt werden. Die neue Methode wird in der Medizin, in der Überwachung von Produktionsprozessen und in der Umwelt‐ und Lebensmittelanalytik Anwendung finden. Auch bei der Erforschung von Adsorptionsvorgängen und Oberflächeneffekten können die Projektergebnisse genutzt werden.

Determination of activity coefficients from partial excess Raman spectra (DFG-project)

Since November 2022, the project “Determination of activity coefficients from partial excess Raman spectra” has been running at ITUN.

Fluid phase equilibria are essential for the design of thermal separation processes. They usually have to be determined experimentally, which involves considerable effort.

For real mixtures, fluid phase equilibria can be predicted by considering the activity coefficients 𝛾𝑖 of the mixture compounds. The activity coefficients can be derived from the partial molar excess Gibbs energy . Just like the thermodynamic mixture quantities, Raman spectra of a real mixture also have an excess part. Both mixture properties, the excess spectrum of the mixture and the molar excess Gibbs energy are attributed to intermolecular interactions, which exist only in the mixture, but not in the pure substances.

This feature of real Raman spectra is to be used within the DFG-funded project "Determination of activity coefficients from partial excess Raman spectra" in order to being able to predict activity coefficients using excess Raman spectra of single-phase liquid mixtures. Various machine learning methods will be used for this purpose. Compared to the conventional measurement of phase equilibria, this approach requires significantly less experimental effort.

We are very much grateful to the German research foundation for funding this project.

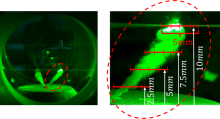

Fine exploration of the rock salt contour in the area of future closure structures in HAW repositories by in situ Raman spectroscopy (BMUV-project)

The project Fine exploration of the rock salt contour in the area of future closure structures in HAW repositories by in situ Raman spectroscopy (SaRa) was started on July 2023 as a joint project between ITUN and IfAC at TU Freiberg.

As sites for future HAW repositories, deep geological formations in the three hosts namely rocks salt, clay/claystone and crystalline rock (granite) could be used. Once the site has been chosen, constructed and operated by the repository, the emplacement areas must be permanently sealed off by suitable geotechnical barriers after completion of the operational phase. These must be positioned in the intact rock in order to prevent or minimize a possible flow around them. An anisotropy of the rock permeability can possibly reduce the sealing effect. Even small, higher permeable areas in the contact zone with preferred flow paths can lead to a local flow around the sealing elements.

So far, in the case of rock salt contour as HAW repositories, the composition of the surrounding rock salt has only been determined by selective individual analyses of drill core material or material from the post-cut. A spatially resolved in situ mineral analysis is not possible with the current scientific and technical possibilities. In the current available method, the attention has been paid to visually conspicuous appearances of continuous bands, as it is known that preferred flow paths for a flow around the surrounding mountain area can form at the boundaries of the layers. Visually unnoticeable areas of the mountain contour with easily soluble minor components are usually not detected.

Through this project, a spatially resolved in situ method for mineral phase analysis, which can be coupled with 3D imaging is proposed. Raman spectroscopy can be considered as an analytical method for this purpose, as portable devices are now available or such devices can be specially designed in contrast to X-ray phase analysis (XRD), which can only be carried out on drill core material in laboratories above ground.

We thank the Federal Ministry for the Environment, Nature Conservation, Nuclear Safety and Consumer Protection (BMUV) for funding this project.

Mixing at transcritical conditions (DFG-project)

DFG project "Mixing at transcritical conditions"

In March 2024, the project “Mixing at transcritical conditions” is going to start at ITUN.

In the application of technical high-pressure injection systems, e.g. propulsion systems or high-pressure processes for particle generation, modelling processes is a common praxis as experimental data are rare and need a lot of effort.

For real injection trajectories, several models are trying to predict these processes by considering heat and mass transfer. All these models have in common, that they underly certain assumptions to predict the process. On the other hand, only a few experimental data at simplified conditions are available which is not sufficient to assess the capacities of the respective models.

This leakage of available data can be filled by in-situ Raman measurements within the DFG-funded project "Mixing at transcritical conditions". With this technique simultaneously, the quantitative mixture composition and the temperature along real transcritical mixing paths of trajectories can be determined. With this knowledge in mind a comparison of real vs. theoretical mixing can be drawn for further improvements in modelling transcritical mixing.

We are very much grateful to the German research foundation for funding this project

EFRE validation project: Can TUBAF liquid-core waveguides help to make the process industry more efficient? (Co-funded by the European Union and from tax revenues on the basis of the budget adopted by the Saxon State Parliament)

The validation project launched at ITUN on November 1 (funding no. 100689010) is getting to the bottom of this question. The liquid-core waveguides consist of thin capillaries whose walls are coated on the inside with highly porous, hydrophobic aerogel (https://doi.org/10.3390/s22124388). When a liquid sample is flowing through the hollow core of the aerogel-lined capillary, light can also be guided through the capillary - via total internal reflection at the interface of the aerogel lining and the liquid sample. In the process industry, these liquid-core wave guides could be used to monitor chemical reactions in production processes in real time using spectroscopy. Here, the liquid aqueous sample is fed from a reactor into the hollow core of an aerogel-lined capillary. The excitation light is then coupled through a small window into the liquid aqueous sample contained in the hollow core of the aerogel-lined capillary. Finally, the light emitted through a window on the other side of the aerogel-lined capillary is analyzed in order to quantify the concentration of reaction products contained in the liquid sample. This opens up the potential to control energy-intensive chemical production processes more precisely and thus make them more energy-efficient and sustainable. Within the validation project, the manufacturability of the aerogel-lined capillaries will be validated for the requirements of selected processes of various pilot companies. The project will run for 18 months.

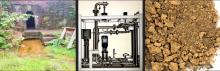

rECOmine: Recycling of ferruginous mine sludge and waste water treatment in a multi-stage field test laboratory (BMBF)

Accumulated sludge produced in (formerly) mine water facilities is a major environmental problem and is usually only treated as hazardous waste and deposited in landfills or backfill mines. Due to the continuous wash-out of ore material large concentrations of heavy metals and other materials accumulate within the water drawing system.

Within the BMBF funded project “rECOmine ZauBer - Future materials from mining sludge” (started in 2022) a field test laboratory at the “Rote Graben” - a mining canal heavily clogged with ferruginous sludge, at Freiberg (Germany) - is built up. On the one hand the pilot-scale system will be used for the continuous treatment of mining waters by a multi-stage membrane pilot-plant. On the other hand, the approximately 13,000 t of iron and heavy metal containing sludge will be recycled to a starting stock for geopolymer building materials by combining a chamber filter press, a precipitation line and a multi-stage membrane plant. At ITUN, the focus of the interdisciplinary project is on the design and construction, process implementation and process optimization of the membrane filtration stage as well as the use in real application environment. In the future, it is planned to use the entire treatment method also at other locations.

We thank the Federal Ministry of Education and Research (BMBF) for funding this project.

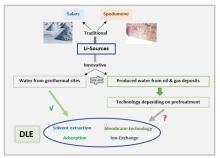

Chances for lithium from oil and gas reservoir waters (DGMK)

A large part of scientific research today is aimed at environmental protection. Topics such as CO2 emissions give rise to many other branches of research that exist today. One of these is the production of e-cars and their consistent further development. And here we come to the point, which is the lithium resources. The largest resources of Lithium are found in South Amerika particularly in Chile und in Argentinia and Australien. From the resources in South America the biggest part is in Chile. However, the resources located in Argentina are smaller than the resources in Australia.

As one of the most important car manufacturers, Germany will benefit considerably and gain a degree of independence if it has access to its own lithium resources and can reduce the amount of imported lithium. This project is about finding the right technology to extract lithium from oil and gas deposits in Germany and Austria. The project commenced in August 2023 and is to be realised in three phases. We are now in the first stage, i.e. through literature research we are trying to identify the most productive combination of technologies to extract lithium from the produced water from these sources.

The project is financed by DGMK and German and Austrian partners from the oil and gas industry. The next two phases of the project will see the development of a multifunctional pilot plant followed by field tests.