Process Engineering & Chemical Engineering

Process engineering and chemical engineering ("VTC" for short) deal with all processes in which substances are changed in terms of their composition, type or properties. They use mechanical, thermal, chemical or biological processes.

The electronic materials in your mobile phone, tablet, laptop or PC were obtained from raw materials using process engineering processes. The plastics, paints, varnishes and foams that surround you were produced from basic chemicals by means of technical processes. The food and luxury foods you consume, as well as pharmaceuticals, are produced from natural substances using technical processes. Hydrogen, the energy source of the future, is produced using technical processes. The greenhouse gas carbon dioxide is "captured" and deposited in landfills by means of technical processes or converted into chemicals, fuels and products by means of technical processes. Municipal and industrial residues (waste), wastewater and exhaust air streams are treated, purified and/or recycled using process engineering processes. This list could go on and on. You will have realised by now that the VTC represents highly relevant future technologies for our supply of a healthy environment, energy, basic chemicals and food and that the areas of application for VTC graduates are almost endless.

The first half of the VTC diploma programme is therefore designed to enable you to quickly familiarise yourself with new tasks with varying requirements based on a very comprehensive basic education (in natural sciences and engineering). You will not only familiarise yourself with these scientific and engineering fundamentals, but also learn to understand them. This small but subtle difference is crucial for you to be able to transfer and apply your knowledge to new challenges later on and to assess your ideas and the ideas of others in terms of their usefulness and feasibility.

You not only need to know what is theoretically feasible, but also be able to assess what you can implement given the resources available to you. Which materials are compatible with which chemicals? Which pumps, compressors, heat exchangers, valves, reactors, columns, separators, mills are best suited to my project and what is affordable? How do I interconnect the material flows to be heated with the material flows to be cooled so that my process later requires the minimum amount of energy? Do I produce the product in the gas phase or in the liquid phase, continuously or in a batch process, with a homogeneous or heterogeneous catalyst, in a multiphase or a single-phase process? How can the process be controlled? These are just a few of the questions that you will have to think about later when developing and planning process engineering processes. Don't worry! You won't have to do this for the first time as a job newcomer!

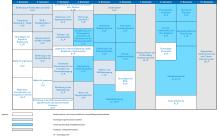

The second half of the VTC diploma programme is designed to build on the broad basic knowledge you have already acquired, so that you can get to know and understand the various areas of process engineering and chemical engineering and its methods in depth. If you are particularly interested in one area, you can choose modules in this area for particularly intensive further training, but you also have the option of spreading your elective modules across the entire spectrum of process engineering and chemical engineering. Of the 300 credit points that you have to earn by the time you graduate, only 200 credit points are strictly prescribed by the examination regulations. With the remaining 100 credit points, you can develop your interests further, for example by choosing a thesis topic or subject that appeals to you, by choosing what appeals to you from the catalogue of compulsory elective modules and free elective modules and by completing your practical semester in an environment/company or possibly an international research institution that appeals to you. This means that this university degree programme is not short on practical experience. You will also have the opportunity to gain international experience and study in a scientific environment.

What else needs to be said:

When we revised the Process Engineering & Chemical Engineering degree programme together with dedicated students at our faculty in 2020, the following was very important to us in terms of studyability:

- No more than five exams per examination period, usually only four exams per examination period. You don't have to rush from exam to exam! You have the time and opportunity to really get to grips with the material and learn it for long-term memory.

- Early contact (from the second semester) with modules with procedural applications and reference to current research work. This keeps your motivation for your studies at a high level even during the otherwise long "dry spell" of basic scientific and engineering training (first four semesters).

- Individual options by choosing compulsory elective modules from a predetermined module catalogue and by choosing free elective modules. You can develop flexibly according to your engineering interests and have the opportunity to think outside the box.

- You will gain practical and research experience in the basic internship, during specialist excursions, a student research project, a specialist internship, a dissertation and a diploma thesis.

- An education in the specialist language of English and introductory business administration will also provide you with the basis for success in an international environment.

We, the study committee, are convinced that this degree programme will prepare you excellently for future job profiles in industry and science and that you will be able to develop individually according to your interests.

We will be happy to support you. If you have any questions about the degree programme, please feel free to give us a call.

- Faculty

-

Faculty of Mechanical, Process and Energy Engineering (Faculty 4)

- Degree

-

Diploma (Dipl.-Ing.)

- Standard period of study

-

10 Semester

- Part-time possible

-

No

- Start of studies

-

Winter semesterSummer semester

- Admission requirement

-

Abitur or subject-specific higher education entrance qualification or an entrance qualification recognised as equivalent

Language requirement

- Application: with at least B1 level German

- Admission to the degree program: with C1 level German (e.g. DSH-2)

- language courses and DSH exam at TUBAF

- Course language

-

German

Research and development as well as project planning, operation and maintenance of process engineering equipment and systems, including in the chemical industry, energy industry, battery (recycling) industry, ceramics, glass and building materials industry, mining and processing, wastewater treatment, waste disposal and treatment, air pollution control, food industry, heating and air conditioning technology, biotechnology, mechanical and plant engineering

- Management and logistics

- Engineering offices

- Teaching and research: e.g. university, Fraunhofer Society, Max Planck Institutes

- Public sectore.g. university, Fraunhofer Society, Max Planck Institutes

- Public service: e.g. authorities, TÜV, local authorities, utilities and waste disposal companies, municipal utilities

- Economic and professional associations, consultancy

- Professional activity: e.g. appraiser, industrial consultant, patent attorney

Why study Process Engineering & Chemical Engineering at TUBAF?

- Because the needs of the students were strongly taken into account when creating the degree programme (manageable number of examinations, stringent study options, elective options, application and research relevance at an early stage of the degree programme)

- because you value short distances and personal contact with lecturers

- because you would like to benefit from the lecturers' international contacts and would like support in organising a semester abroad or your Bachelor's thesis at an international research institution (we are happy to arrange this)

- . (we will be happy to put you in touch)

- because you would like to work as a paid research assistant on current research projects and thus gain an insight into current research (we need your support for our research projects)

- because TUBAF has excellent contacts with funding organisations:within that support our students in the form of scholarships (scholarship chances are quite high!)

- because we prioritise our students, precisely because we are a small but very research-intensive university. Our graduates are also our doctoral students of tomorrow, with whom we are happy to research the challenges of the future together!

- because life (including housing) in Freiberg is not as overpriced as in some other university towns

Interests and skills you should bring with you

Basic understanding of maths and science subjects. No advanced course level required. Much more important are an interest in process engineering/chemical engineering, enthusiasm for new things, perseverance and a little self-discipline and ambition.

A 6-week basic internship is required for this degree programme (30 working days). Completion or partial completion before the degree programme (after the Abitur) is recommended. The internship can also be completed during the degree programme. Requirements for the basic internship can be found in the download opposite. Dr Dög will be happy to answer any questions you may have (see the box on the right "Specialist advice").