Effizienzsteigerung bei der Bauteilauslegung durch den Einsatz schädigungsmechanischer Simulationsmethoden

Bei der Auslegung eines Bauteils im Maschinen-, Anlagen- und Fahrzeugbau muss nachgewiesen werden, dass es den im Betrieb zu erwartenden Belastungen standhält und sicher betrieben werden kann. Dabei ersetzen computergestützte Methoden zunehmend die aufwändige und kostenintensive experimentelle Verifikation und tragen so wesentlich zu einer höheren Effizienz und schnelleren Entwicklungszyklen bei.

Die schadenstolerante Auslegung stellt sicher, dass Defekte, die bei der Herstellung oder im Betrieb durch Materialermüdung oder Korrosion auftreten können, nicht zum Ausfall eines Bauteils im Betrieb führen.

Derartige Betrachtungen sind in vielen sicherheitsrelevanten Bereichen bereits vorgeschrieben und ermöglichen zusätzlich einen effizienteren Materialeinsatz. Etablierte Methoden wie die Bruchmechanik sind in manchen Fällen sehr konservativ, was Freiraum zur Verbesserung birgt.

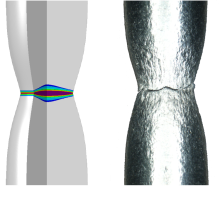

Prinzipiell erlauben schädigungsmechnische Computersimulationsverfahren genauere Vorhersagen über die Kritikalität von Materialfehlern und Ausfällen. Allerdings erfordern solche Simulationen die iterative Bestimmung der Modellparameter auf der Basis spezieller Tests und damit ein hohes Maß an Spezialwissen.

Das an der TU Bergakademie Freiberg entwickelte Modell lässt sich durch ein schrittweises Vorgehen auf der Basis von konventionellen Normversuchen einfach kalibrieren, was für bestimmte Stahlsorten bereits erfolgreich demonstriert wurde.

Veröffentlichungen

- A. Seupel, G. Hütter, M. Kuna, On the identification and uniqueness of constitutive parameters for a non-local GTN-model, Engineering Fracture Mechanics 229 (2020) 106817.

- G. Hütter, T. Linse, U. Mühlich, M. Kuna, Simulation of Ductile Crack Initiation and Propagation by means of a Non-local GTN-model under Small-Scale Yielding, International Journal of Solids and Structrures 50 (2013) 662-671.

- D.R. Pham, O. El Khatib, A. Seupel, G. Hütter, B. Kiefer, Iterationslose Bestimmung der Parameter des Gurson-Modells aus zwei genormten Versuchen, DVM-Bericht 254 (2022), 43-52

- O. El Khatib, G. Hütter, R.-D. Pham, A. Seupel, M. Kuna, B. Kiefer: A non-iterative parameter identification procedure for the non-local Gurson-Tvergaard-Needleman model based on standardized experiments, International Journal of Fracture 241 (2023) 73-94

Download der Implementierung

Die Implementierung des nichtlokalen GTN-Modells steht über die UMAT-Schnittstelle in Abaqus/Standard und durch die VUMAT-Schnittstelle in Abaqus/Explicit zur Verfügung. Bei der UMAT-Schnittstelle steht als Sonderfall das lokale GTN-Modell zur Verfügung (welches in Abaqus/Explicit standardmäßig enthalten ist).

Zip-Download

Förderung

Dieses Forschungsvorhaben wurde im Zeitraum 05/2021 bis 10/2022 unter der Projektnummer 100544457 aus Mitteln des Europäischen Fonds für regionale Entwicklung (EFRE) und aus Steuermitteln auf Grundlage des vom Sächsischen Landtag beschlossenen Haushaltes finanziert.